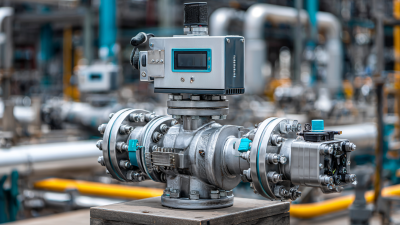

In modern industrial processes, the precise control of fluid flow is crucial for ensuring operational efficiency and safety. Central to this control are valve positioners, devices that ensure valves are positioned accurately according to the demands of the system. Selecting the right valve positioner can significantly enhance the performance and reliability of any fluid control system. As we move toward 2025, the variety of valve positioners available on the market has expanded, making the selection process more complex yet more essential than ever.

Understanding the key factors involved in choosing a valve positioner is vital for engineers and system designers. Factors such as sensitivity, response time, compatibility with existing systems, and the specific requirements of the application must be carefully considered. Additionally, the integration of advanced technologies, such as digital communication protocols and smart automation, can further influence the choice of valve positioner, helping to optimize system performance and reduce operational costs. This guide aims to provide insights into how to effectively navigate these considerations, ultimately aiding in the selection of the most appropriate valve positioner for your system.

Valve positioners play a crucial role in enhancing the functionality and performance of control valves in various industrial applications. Understanding the different types of valve positioners—such as pneumatic, electrical, and digital—is essential for selecting the right one for your system. Pneumatic positioners are widely used for their reliability and cost-effectiveness, making them ideal for traditional control systems. Electrical positioners, on the other hand, offer increased precision and faster response times, which can be advantageous in more complex setups. Digital positioners combine advanced algorithms and automation capabilities, providing real-time monitoring and diagnostics.

When choosing a valve positioner, consider the specific requirements of your system, such as the required accuracy, response time, and compatibility with existing control systems. Tips for selection include assessing the environment in which the positioner will operate; for instance, high temperatures or corrosive conditions may necessitate specialized materials. Additionally, ensure that the actuator’s characteristics align with the positioner's capabilities for optimized performance.

Lastly, it's essential to evaluate the operational complexities of your process. For applications requiring precise adjustments, a smart or digital positioner may deliver superior results. Always consult with technical experts when in doubt, as they can provide invaluable insights tailored to your system's needs.

When selecting a valve positioner for your system, several critical factors should be considered to ensure optimal performance and reliability. First, assess the type of valve and actuator you are using, as compatibility is key. Different positioners are designed for particular valve types, including linear and rotary valves, which directly influence the choice of positioner. Additionally, understanding the actuator’s specifications, such as required torque and response time, will help in selecting a positioner that can effectively control the valve.

Another essential factor is the environment in which the valve positioner will operate. Evaluate conditions such as temperature, humidity, and potential exposure to corrosive substances. Selecting a positioner with appropriate ingress protection (IP rating) can safeguard against environmental hazards, ensuring longevity and consistent performance. Other considerations include the communication protocols required for integration into your existing system, ease of calibration, and diagnostic capabilities that can provide insight into performance and maintenance needs. Making informed decisions based on these factors can significantly enhance your system's efficiency and reliability.

When selecting the right valve positioner for your system, assessing system compatibility and performance requirements is crucial. According to a recent industry report by ARC Advisory Group, over 50% of industrial automation failures can be traced back to inadequate system integration. This statistic emphasizes the necessity of understanding your existing control architecture before investing in a valve positioner. Compatibility entails examining communication protocols, input/output specifications, and power requirements, ensuring that the new positioner seamlessly integrates with your current system.

Tip: Conduct a thorough audit of your existing system before beginning the selection process. Document the existing protocols, signal types, and loads to facilitate a more informed decision on which positioner will complement your setup effectively.

Performance requirements must also be defined clearly. Factors such as response time, accuracy, and environmental conditions should be considered. A study by IHS Markit found that improper selection of valve positioners led to a 20% increase in operational inconsistencies and downtime. Matching the positioner’s specifications with your operational demands can mitigate risks and enhance efficiency.

Tip: Utilize simulation tools to model your system’s dynamics and predict the impact of different positioners under varying conditions. This proactive approach can reveal insights that lead to improved performance and reliability in the long run.

When selecting a valve positioner for your system, understanding the key features of modern valve positioners is crucial for optimizing performance and efficiency. One fundamental aspect to consider is the responsiveness of the positioner. Advanced models utilize digital technology to provide quicker response times, allowing for precise control over valve movements. This is particularly beneficial in applications where process dynamics can change rapidly, ensuring that the system maintains stability and operates within desired parameters.

Another essential feature is the integration of advanced diagnostic capabilities. Modern valve positioners often come equipped with built-in diagnostics that monitor performance and provide real-time feedback. This capability can help identify issues before they escalate into significant problems, improving reliability and decreasing downtime. Additionally, many devices feature intuitive interfaces that allow for easy programming and adjustment, enabling operators to customize settings based on operational requirements effortlessly. By focusing on these key features, you can make informed decisions that enhance the efficiency and reliability of your valve control system.

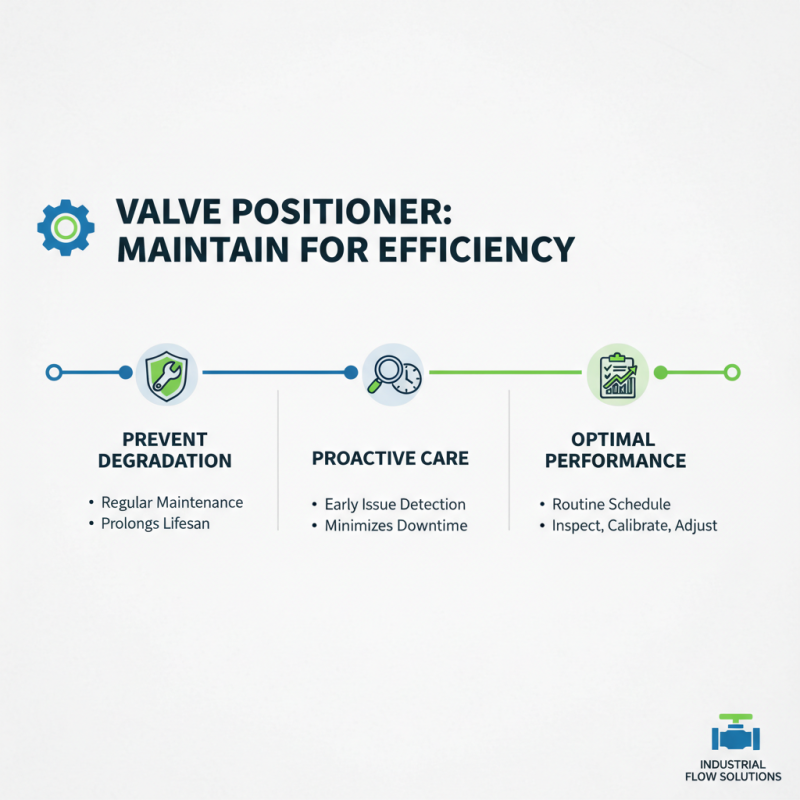

When selecting a valve positioner for your system, ongoing maintenance and support play critical roles in ensuring long-term efficiency. Regular maintenance prevents performance degradation, thereby prolonging the lifespan of both the valve positioner and the entire system. A proactive approach to maintenance can identify potential issues before they escalate, allowing for timely interventions that minimize downtime and costly repairs. It is essential to establish a routine maintenance schedule that includes inspections, calibrations, and necessary adjustments.

**Tip:** Document all maintenance activities meticulously. Keeping detailed records can help identify recurring issues, facilitate compliance with industry standards, and streamline any troubleshooting processes that arise.

Choosing a supplier that offers robust support services is equally important. Look for vendors that provide comprehensive technical assistance, training sessions, and access to spare parts. This support network can significantly enhance the performance and reliability of your valve positioners and systems. Engaging with a supplier that prioritizes customer engagement ensures that you receive timely updates and solutions tailored to your specific application requirements.

**Tip:** Consider setting up regular check-ins with your support provider to discuss system performance and potential upgrades. This proactive collaboration can lead to continued improvements and adaptations as your operations evolve.

1272 Speers Rd Unit 4

Oakville ON Canada L6L 2X4

©Copyright 2020 Gosco Valves. All rights reserved.