In the realm of industrial applications, the precision and reliability of processes are paramount. One crucial component that significantly enhances operational efficiency is the valve positioner. According to Dr. John Mitchell, a leading expert in the field of process automation, "The use of a valve positioner not only improves the accuracy of valve control but also optimizes the entire system’s performance." This statement underscores the vital role that valve positioners play in ensuring that control valves respond accurately to commands, resulting in improved process stability and reduced costs.

Incorporating a valve positioner into industrial systems offers several key benefits, including enhanced control, reduced wear on valve components, and minimized energy consumption. As industries strive for greater efficiency and sustainability, the integration of valve positioners becomes increasingly important. By precisely managing the valve's position, these devices help maintain optimal flow rates and pressure levels, ultimately leading to better resource utilization. In this era of advanced automation and smart manufacturing, understanding the advantages of valve positioners is crucial for professionals seeking to elevate their operational capabilities.

In industrial settings, valve positioners play a crucial role in ensuring the precise control of flow and pressure within various systems. These devices provide feedback to control valves, allowing them to achieve the desired position more effectively. According to a report by MarketsandMarkets, the global valve positioner market is projected to grow from $1.06 billion in 2020 to $1.46 billion by 2025, signaling an increasing adoption of these technologies across numerous industries such as oil and gas, water and wastewater, and chemical processing.

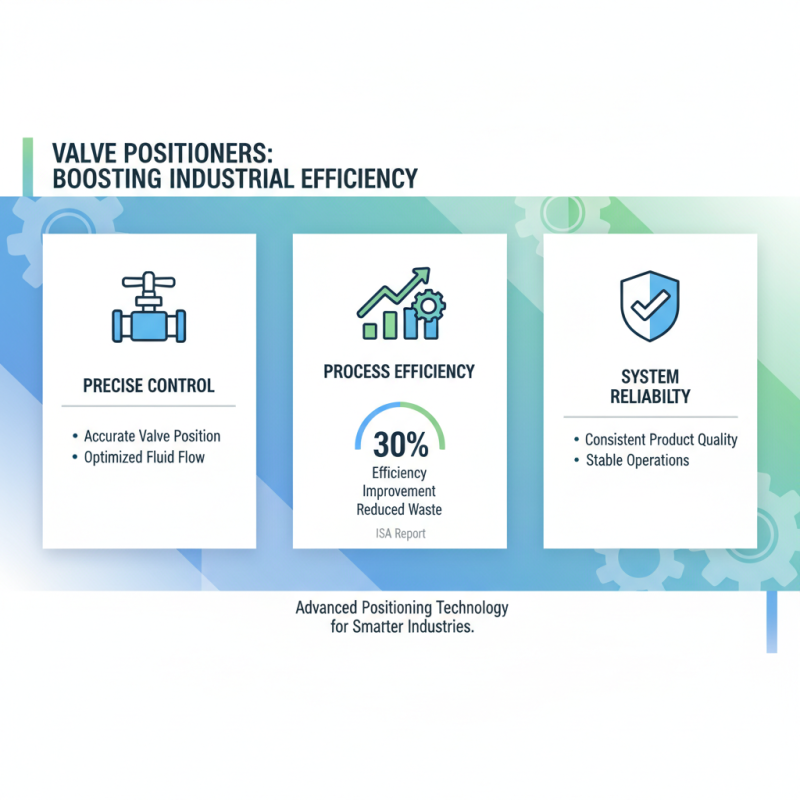

The functionality of a valve positioner enhances process efficiency and reliability. By translating the control signal from a process controller into mechanical movement, these devices reduce the time it takes for the valve to react to changes in system conditions. This improvement in responsiveness is essential in industries where precision and timely adjustments can significantly impact product quality and operational safety. Furthermore, a study from the International Society of Automation indicated that employing advanced positioners can lead to a reduction in energy consumption by up to 30%, highlighting their importance not only for operational effectiveness but also for sustainability initiatives.

In addition to efficiency gains, the integration of valve positioners contributes to better diagnostics and data collection within industrial processes. Modern positioners are equipped with smart technology that allows for real-time monitoring of valve performance and alerts operators to potential issues before they escalate. This capability not only minimizes downtime but also optimizes maintenance strategies. With the ongoing push for digital transformation in industrial applications, valve positioners are becoming integral to achieving higher levels of automation and operational excellence.

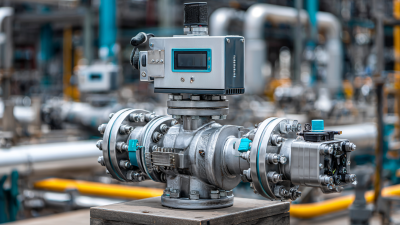

Valve positioners play a crucial role in industrial processes by ensuring that valves operate at precisely the required positions. These devices are designed to control the mechanical movement of a valve in response to a control signal from a process controller. By doing so, valve positioners enhance the accuracy and responsiveness of the valve, which is essential in maintaining the desired flow rates and pressures within a system. Their functionality allows for fine-tuning of control performance, resulting in improved process efficiency and stability.

Additionally, valve positioners contribute to the system's overall reliability. They compensate for disturbances and variations in the process conditions, ensuring that the valve maintains its set position even when faced with external factors, such as changes in pressure or fluid characteristics. This adaptability not only prolongs the life of the valve but also minimizes the risk of mechanical failure or erratic behavior, which could lead to costly downtimes. By understanding how valve positioners function, industries can better implement them into their systems, ultimately achieving enhanced performance and operational safety.

| Benefit | Description | Applications | Impact on Efficiency |

|---|---|---|---|

| Precision Control | Improves accuracy in process control by minimizing hysteresis and dead time. | Oil & Gas, Chemical Processing | Increases overall process stability. |

| Reduced Wear | Decreases mechanical wear on valve components by providing soft starts and stops. | Water Treatment, HVAC Systems | Prolongs equipment lifespan and reduces maintenance costs. |

| Enhanced Safety | Provides feedback on valve position, enabling faster response to emergency shutdowns. | Pharmaceutical, Power Generation | Reduces risk of accidents and enhances operator safety. |

| Energy Savings | Optimizes energy consumption by precisely controlling the flow and pressure. | Food Processing, Pulp and Paper | Lowers operational costs through efficient resource management. |

| Remote Monitoring | Allows for real-time monitoring of valve operation from a distance. | Mining, Offshore Operations | Facilitates quicker decision making and reduces downtime. |

Implementing valve positioners in industrial applications offers several key advantages that significantly enhance operational efficiency and control. One of the most notable benefits is improved accuracy in valve positioning. According to a report by the International Society of Automation (ISA), facilities using valve positioners can achieve positioning accuracy of up to 99%. This high level of precision enables better process control, leading to reduced waste and optimized resource usage.

Additional data from the American Petroleum Institute (API) indicates that assets equipped with valve positioners can experience a 20-30% reduction in energy consumption, contributing to sustainability initiatives within industrial operations.

Another important advantage of valve positioners is their ability to enhance responsiveness to control signals. By ensuring that the valve opens or closes promptly to the desired position, these devices minimize the lag time in process adjustments, which is essential for maintaining product quality and system integrity. The Fieldbus Foundation has reported that utilizing valve positioners can improve system response times by as much as 50%, enabling manufacturers to react swiftly to changing market demands or operational conditions.

Tips: When considering the implementation of valve positioners, conduct a thorough assessment of your current system's performance to identify specific areas where improvements could be made. Additionally, ensure that your team is properly trained in the calibration and maintenance of valve positioners to fully leverage their advantages in industrial settings.

The implementation of a valve positioner in industrial settings significantly enhances process efficiency and control accuracy. A valve positioner provides precise control of valve position, ensuring the flow of fluids is optimized according to the demands of the process. According to a report by the International Society of Automation, optimizing control processes with advanced positioning technology can lead to efficiency improvements of up to 30%. This is particularly vital in complex systems where accurate flow regulation is necessary to maintain product quality and operational consistency.

Moreover, the use of valve positioners minimizes the risk of valve stiction, a common issue that can lead to unstable control loops and wasted resources. The American Institute of Chemical Engineers highlights that addressing stiction can improve system reliability and response time, leading to reductions in downtime by approximately 20%. By enhancing control accuracy, valve positioners also contribute to energy savings, as they help prevent over-adjustment of valves, which can lead to excessive energy consumption.

**Tips:** When implementing a valve positioner, ensure proper calibration to achieve optimal performance. Regular maintenance checks can also prevent common issues such as stiction, allowing for sustained efficiency and reliability in operations. Additionally, training personnel on effective monitoring and control techniques can further enhance the benefits of valve positioners in your processes.

The use of valve positioners in industrial applications offers significant maintenance and longevity advantages that can greatly enhance system reliability and performance. According to a report by the Institute of Electrical and Electronics Engineers (IEEE), systems equipped with valve positioners experience up to a 30% reduction in valve wear and tear compared to those without. This reduction stems from the precise control that positioners provide, ensuring that valves reach their desired positions more accurately and quickly, thus minimizing the mechanical stress associated with over or under travel.

In addition to prolonging the lifespan of valves, installing positioners can lead to more straightforward maintenance routines. A study conducted by the International Society of Automation (ISA) indicates that incorporating smart valve positioners can decrease maintenance costs by approximately 20% over the lifecycle of the equipment. These advanced positioners often come equipped with diagnostic features that provide real-time performance data, allowing maintenance teams to identify issues before they escalate into costly failures. As industrial systems continue to evolve, the integration of valve positioners will play a crucial role in optimizing operational efficiency and reducing long-term maintenance needs.

1272 Speers Rd Unit 4

Oakville ON Canada L6L 2X4

©Copyright 2020 Gosco Valves. All rights reserved.