In the realm of industrial automation, selecting the right control valve is crucial for ensuring efficient operation and optimal performance of systems. According to John Smith, an esteemed expert in the control valve industry, "Choosing the right control valve can significantly affect the reliability and efficiency of your entire process." This statement underlines the importance of a thoughtful and informed approach to valve selection, as it can lead to substantial improvements in productivity.

Control valves serve a fundamental role in regulating fluid flow and maintaining desired process conditions. As industries evolve and technologies advance, the complexity of choosing the ideal control valve has increased, demanding a comprehensive understanding of various factors, including valve types, materials, and operational requirements. Furthermore, as processes become more sophisticated, the need for precision and reliability in control valves becomes paramount. Thus, exploring the best practices for selecting control valves tailored to specific industrial needs is essential for achieving effective system management and enhancing overall operational success.

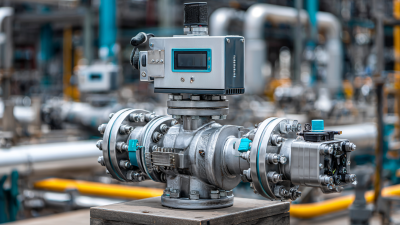

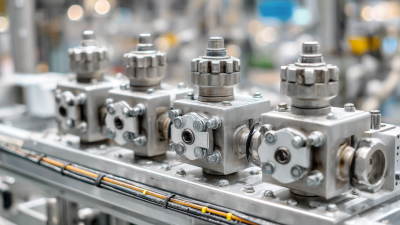

When selecting the right control valve for industrial applications, it's essential to understand the various types available and their specific functionalities. Control valves can be categorized into several main types: globe, gate, ball, and butterfly valves.

Globe valves are commonly used for throttling purposes due to their efficient flow control. Gate valves, on the other hand, are ideal for fully opening or closing applications, providing minimal pressure loss.

Ball valves are favored for their quick operation and tight sealing capabilities, making them suitable for on-off control in high-pressure systems. Butterfly valves are noted for their lightweight and compact design, often employed in large flow applications where space is limited.

Each type has unique features that cater to different industrial needs, such as temperature tolerance, pressure handling, and flow characteristics. Understanding these distinctions is crucial for optimizing performance and ensuring the longevity of the valve in various industrial settings.

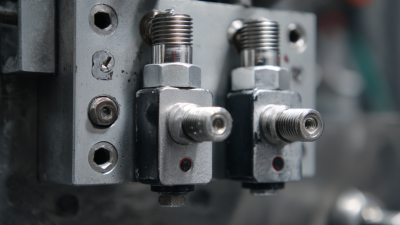

When selecting the right control valve for industrial applications, several key factors should be considered to ensure optimal performance and efficiency. One crucial aspect is the type of media being controlled—liquids, gases, or steam—which influences the valve design and materials used. Additionally, the operating conditions, including pressure, temperature, and flow rates, play a significant role in determining the appropriate valve type. Compatibility with existing systems is also vital, as mismatches can lead to operational failures or increased maintenance costs.

In the context of the growing market for high-purity valves, the industry is projected to reach $2.26 billion in 2024 and is expected to grow to $3.45 billion by 2033, with a compound annual growth rate of 4.81%. This trend highlights an increasing demand for reliable and precise control devices across various sectors, particularly in manufacturing and healthcare. Furthermore, advancements in technologies such as piezoelectric valves, which are gaining traction due to their efficiency and responsiveness, indicate a shift towards automation and enhanced process control. Assessing these market dynamics is essential for making informed decisions in control valve selection, ensuring alignment with industrial growth trajectories.

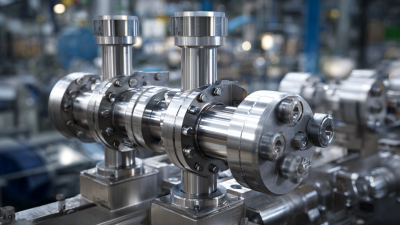

When selecting the right control valve for industrial applications, evaluating the materials and their compatibility with fluids is paramount. According to a report by the Control Valve Market Analysis (2022), over 20% of valve failures are attributed to material incompatibility with process fluids. This statistic underscores the need for careful consideration of the materials used in control valves, especially when dealing with aggressive media such as acids, solvents, and high-temperature fluids.

Materials such as stainless steel, titanium, and various types of polymers offer distinct advantages based on the application. For instance, stainless steel valves are widely used due to their corrosion resistance and strength, making them suitable for a variety of fluids. In contrast, polymers can provide excellent resistance to specific chemicals, but their performance might be compromised at elevated temperatures. Industry reports suggest that assessing chemical compatibility charts and engaging with material experts can significantly enhance the longevity and operational efficiency of control valves, ultimately reducing maintenance costs and downtime in industrial settings.

Selecting the right control valve for industrial applications is a critical decision that directly impacts operational efficiency and safety. One of the primary considerations in selecting a control valve is adhering to industry standards and compliance regulations. According to the International Society of Automation (ISA), approximately 30% of control valve failures can be attributed to improper selection and inadequate compliance with standards such as ISA-75 and API 598. Understanding the specifications and performance capabilities that these standards outline can facilitate a more informed selection process.

Moreover, the European Commission's recent report estimates that adherence to regulatory standards can reduce operational downtime by as much as 20%. Compliance not only involves selecting valves that meet trending industry standards but also ensuring that they are properly rated for the conditions they will face—such as pressure, temperature, and fluid characteristics. For instance, the ASME B16.34 standard lays out crucial criteria for valve design and testing, highlighting the importance of selecting valves that have been rigorously evaluated for safety and performance. This attention to compliance can lead to significant cost savings and improvements in system reliability over the lifetime of the equipment.

When selecting the right control valve for industrial applications, understanding sizing and flow characteristics is crucial. According to a recent report by the Flow Control Institute, nearly 30% of valve failures can be traced back to improper sizing. This emphasizes the importance of accurately determining the valve size that correlates with the specific flow requirements of your process. Engineers must consider not just the pipe diameter, but also the flow rate, pressure drop, and the nature of the fluid being controlled.

**Tips:** Always refer to the valve manufacturer’s sizing tools or consult with specialists to obtain precise calculations. Using software simulations can also greatly improve accuracy in predicting valve performance under varying operational conditions.

Flow characteristics, such as the valve's Cv (flow coefficient), further play a significant role in ensuring optimal operation. A high Cv value indicates a valve that can handle larger flow rates with reduced pressure drop, which is fundamental in maintaining system efficiency. The American Society of Mechanical Engineers (ASME) recommends a systematic approach: evaluating dynamic conditions and factoring in potential changes in flow demands over time.

**Tips:** Keep in mind the application’s unique requirements and consult available industry guidelines to ensure compliance and performance efficiency. Regular performance evaluations of the control valve in the operational ecosystem can lead to better longevity and reliability in industrial applications.

1272 Speers Rd Unit 4

Oakville ON Canada L6L 2X4

©Copyright 2020 Gosco Valves. All rights reserved.