In the realm of industrial projects, selecting the right valves and fittings is crucial for operational success. According to a report by the International Valve and Fitting Association (IVFA), the global market for these components is expected to grow at a steady rate of 4.3% annually through 2026. This growth underscores the importance of choosing high-quality products that meet specific project requirements.

Valves and fittings play a critical role in fluid control systems. Their efficiency can directly impact production processes. Selecting inappropriate components can lead to inefficiencies and increased costs. For example, mismatched materials may cause leaks or system failures. Many projects overlook this aspect, leading to serious repercussions down the line.

Product selection should be based on application needs, pressure ratings, and material compatibility. It's essential to consider factors like temperature variations and corrosive environments. A well-informed decision can substantially improve system longevity. Yet, many designers still make choices based on price alone, without thorough assessment. Reflecting on these choices can bring about better outcomes for future projects.

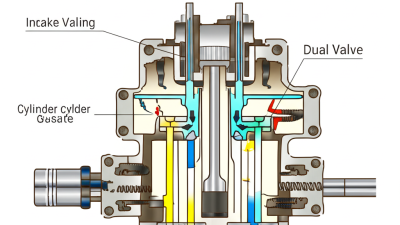

When planning your 2026 projects, understanding valves and fittings is crucial. Different applications require specific types. Valves control the flow of liquids and gases. They can be manual or automated. Fittings connect pipes together. Each fitting has unique features for various needs.

Consider your project's requirements. For high-pressure systems, opt for durable materials. Metal fittings often perform better under pressure than plastic ones. Keep in mind that size matters. Choose fittings that match your pipe diameter precisely. This prevents leaks and ensures efficiency.

Tips: Always check compatibility between your valve and fitting types. You may need adapters for diverse connections. Also, pay attention to the temperature ratings. Some materials degrade quickly in extreme heat or cold. Reflect on past projects. What worked? What didn't? Use this knowledge to make informed choices.

When selecting valves and fittings for your 2026 projects, consider key materials and standards that greatly influence your choices. The right materials ensure durability, longevity, and performance. Materials like stainless steel, brass, and PVC each have specific advantages. Stainless steel is highly resistant to corrosion. Brass offers strength and thermal conductivity. PVC is lightweight and cost-effective.

Tips: Always assess your project's specific needs. Evaluate environmental conditions, media being transported, and temperature ranges. These factors will guide you in choosing the most suitable materials.

Standards play a crucial role in valve and fitting selection. Adhering to industry standards ensures safety and compatibility. ANSI, ASTM, and ISO are important standards to consider. These guidelines provide specifications for quality and performance. Mismatched standards can lead to failures.

Tips: Review the certifications of your components. They should align with your project requirements. This can prevent costly mistakes down the line. Regularly update your knowledge on standards. They change over time and impact your selections.

When selecting valves and fittings for your 2026 projects, performance metrics are crucial. Pressure ratings determine how much force the valve can withstand. For instance, a valve rated for high pressure can handle extreme conditions. On the other hand, the wrong choice can lead to leaks or failures. A mismatch could cause serious project delays and increased costs.

Temperature limits are equally important. They define the range within which a valve operates effectively. High temperatures can weaken materials over time. It's essential to check the specifications. Each project may require different limits. A common mistake is ignoring these metrics. This can result in unexpected challenges down the road. Always assess the operating environment before making a decision.

In evaluating options, consider both metrics together. They are not separate issues. The right combination ensures reliability. Sometimes, the best valve on paper is not the best fit in practice. Reflect on the project’s specific needs. This approach leads to smarter choices in the long run.

| Type | Pressure Rating (PSI) | Temperature Limit (°F) | Material | Applications |

|---|---|---|---|---|

| Ball Valve | 1500 | 400 | Stainless Steel | Oil and Gas |

| Gate Valve | 2500 | 250 | Carbon Steel | Water Supply |

| Check Valve | 1000 | 300 | PVC | Waste Water |

| Globe Valve | 1500 | 350 | Bronze | Steam Lines |

| Pressure Relief Valve | 3000 | 450 | Alloy Steel | Chemical Processing |

When planning a project in 2026, choosing the right valves and fittings is crucial. Quality often comes at a higher price. However, opting for cheaper materials can lead to costly repairs later. It is essential to weigh the benefits against the initial costs.

Reflecting on past projects may reveal that cutting corners didn’t save money in the long run.

A clear cost-benefit analysis helps guide decisions. Consider durability and performance. Sometimes, investing a bit more upfront can save significant funds over time. For example, a high-quality valve may last years longer than a budget option. This reduces the need for replacements. A broken fitting can halt work and impact budget deadlines.

Don’t forget about long-term maintenance costs. Evaluate warranties and after-sales support. Are you comfortable with potential risks? Avoid rushing the selection process. Gathering insights from peers can provide valuable perspectives.

Taking the time to analyze your choices may lead to better outcomes than expected.

As we look toward 2026, the valve and fitting industry is set to embrace significant changes. Innovations are driven by increasing demands for energy efficiency and sustainability. Reports suggest that the global market for valves is projected to reach $87 billion by 2026, reflecting a compound annual growth rate (CAGR) of over 4%. This growth is largely influenced by advancements in materials and smart technology integration.

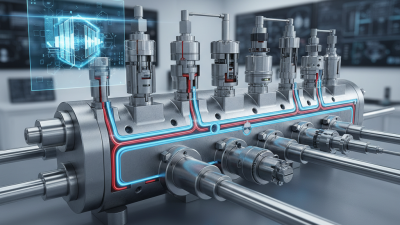

Modern valves are evolving. Many now feature smart sensors that monitor performance in real-time. This can reduce maintenance costs and improve system reliability. A study from the Engineering Society indicates that integrating IoT technology can enhance operational efficiency by 30%. However, many companies still lag in adopting these technologies. They miss opportunities to optimize their processes and reduce waste.

Fittings are also advancing. New designs facilitate quicker installations and tighter seals, minimizing leaks. However, some manufacturers still rely on outdated practices. This reflects a need for industry-wide improvements. Investing in innovative solutions now can help companies meet the demands of 2026 projects, ensuring compliance and enhancing overall functionality.

1272 Speers Rd Unit 4

Oakville ON Canada L6L 2X4

©Copyright 2020 Gosco Valves. All rights reserved.