Choosing the right directional valve can significantly impact the efficiency of your hydraulic systems. Mark Thompson, a renowned expert in fluid mechanics, once said, “Selecting a directional valve is crucial to system performance.” He emphasizes the need to consider both functionality and compatibility.

Directional valves control the flow direction of hydraulic fluids. Their role is critical in various applications, from industrial machinery to mobile equipment. Each application may require a different type of directional valve. Factors such as pressure ratings, port sizes, and operational forces must guide your choice.

Many users overlook compatibility with existing systems. This oversight can lead to costly mistakes and system failures. Reflections on past experiences reveal the importance of proper research and expert consultations. Your choice should be informed and deliberate, ensuring that every detail aligns with your operational needs.

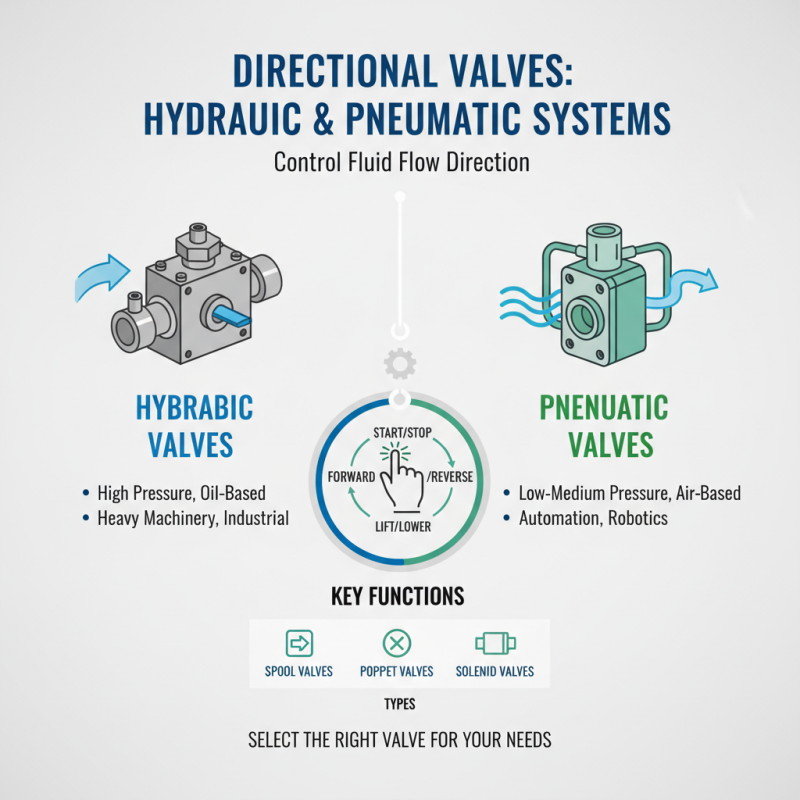

Directional valves play a crucial role in hydraulic and pneumatic systems. They control the flow direction of fluids, enabling various actions in machines. Understanding the types and functions of these valves is essential when selecting the right one for your needs.

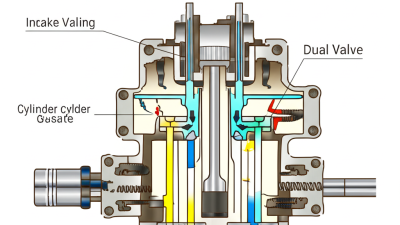

There are several types of directional valves, including spool and poppet valves. Spool valves are often used for their versatility. They can manage flow in multiple directions. Poppet valves provide a more straightforward function, making them easier to use in specific applications. Each type has unique characteristics that can enhance system performance.

Choosing the appropriate valve demands careful consideration. Factors like pressure ratings, port sizes, and actuation types must match your system's requirements. Sometimes, a simple valve may not meet complex needs, leading to inefficiencies. Don't overlook the importance of testing different configurations. This exploration can uncover options that fit your application better.

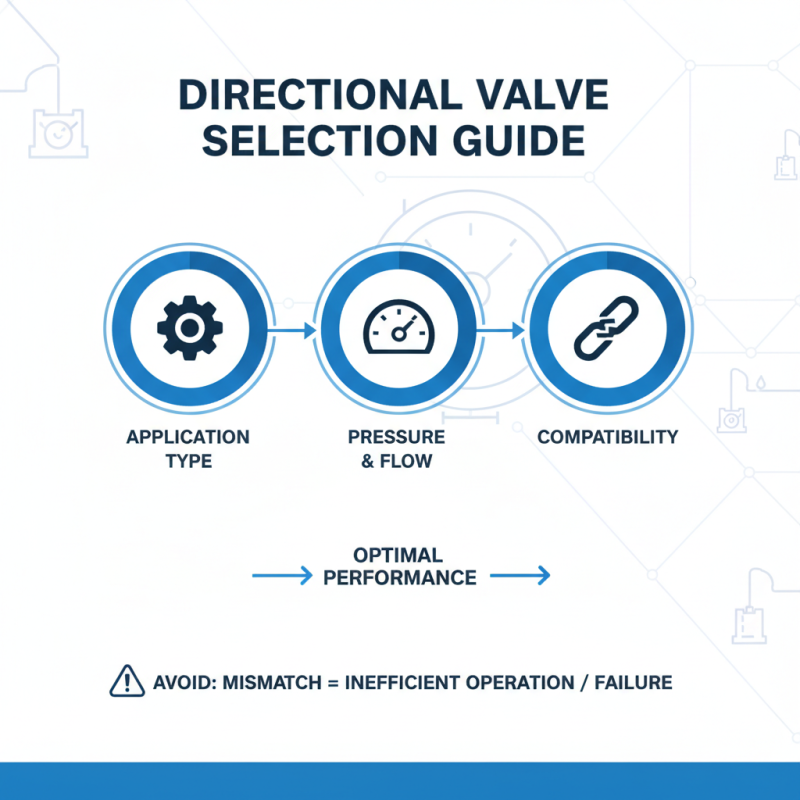

When selecting a directional valve, several key factors come into play. The application is fundamental. Consider the system's pressure and flow requirements. Each valve type handles different conditions. It's crucial to match the valve with specific demands. A mismatch can lead to inefficient operation or even failure.

Another essential factor is the valve's actuation method. Options include manual, pneumatic, and hydraulic actuation. Each has its pros and cons. For instance, manual valves may not be ideal for automated systems. You must evaluate how often valve operation occurs. Automatic solutions often provide better reliability and efficiency.

**Tips:** Always consult with an expert if uncertain about your selection. Test a few options to gauge real-world performance. Measure the response time and durability in your environment. Don't overlook maintenance needs; simpler designs often lead to fewer issues down the line.

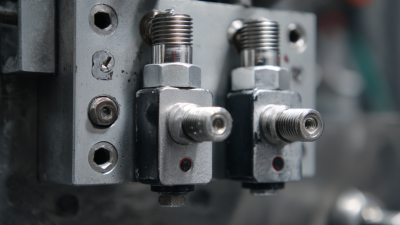

Directional valves play a crucial role in various industrial applications. They control fluid flow and direction, making processes more efficient. In hydraulic systems, these valves ensure that power is directed where it is needed. They enable precise movements in machinery, which is vital. However, the wrong valve choice can lead to inefficiencies.

In the automotive industry, directional valves are essential for braking systems. They help manage fluid pressure and enhance safety. Similarly, in manufacturing, they facilitate automation. Automated machinery relies on these valves for accurate operations. But sometimes, the designs can be overly complex. This complexity may lead to maintenance challenges later.

Agricultural equipment also utilizes directional valves. They assist in operating hydraulic lift systems. This function improves productivity in farming tasks. Yet, mismatched components can cause problems. Understanding specific application needs is vital before selection. Often, users overlook this detail, resulting in performance issues. Careful consideration improves outcomes significantly.

Choosing the right directional valve is crucial. Technical specifications and performance metrics greatly influence your decision. Start by examining the flow rate. This measure indicates how much fluid the valve can handle. Typically, valves have various flow rate options. Identify the requirements of your specific application.

Pressure rating is another essential factor. It determines the maximum pressure the valve can withstand. Ensure that the valve’s pressure rating matches your system’s needs. Leakage rates are also worth considering. High leakage can lead to inefficiency and increased costs in the long run.

Performance metrics should not be overlooked. Check the response time of the valve. A slower response can impair your system's efficiency. Moreover, assess the operating temperature range. Valves need to function well under specific conditions. Each application's demands may differ. Keep this in mind during your selection process.

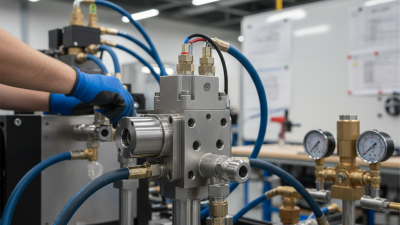

Directional valves play a crucial role in hydraulic and pneumatic systems. Regular maintenance is essential to ensure they operate effectively. Neglected valves can lead to system failure, leaks, and costly repairs. According to a report by the International Fluid Power Society, approximately 25% of all hydraulic failures stem from faulty valves.

Tips for maintenance: Regularly inspect for signs of wear. Look for leaks or unusual noises during operation. Schedule routine checks every six months. Keep the surrounding area clean to avoid dirt contamination. Small particles can jam the valve, impacting performance.

During troubleshooting, focus on symptoms. Is there a delay in response? It may indicate internal damage. Check seals and O-rings. Replacement is often needed but overlooked. Remember, preemptive action can save you time and money in the long run. Regular training for staff can enhance their ability to identify problems early. This proactive approach can improve reliability.

| Attribute | Description | Common Use Cases | Maintenance Tips |

|---|---|---|---|

| Flow Rate | Amount of fluid that can pass through | Hydraulic systems, Pneumatic applications | Regularly inspect for clogs |

| Pressure Rating | Maximum pressure the valve can handle | High-pressure systems | Check seals and O-rings regularly |

| Type of Actuation | Manual, Electric, Pneumatic | Automation, Manual control | Test actuators for responsiveness |

| Size and Porting | Physical dimensions and connection type | Space-constrained designs | Ensure correct fitting and alignment |

| Operating Temperature | Range of temperatures the valve can operate | Extreme environment applications | Monitor for thermal expansion issues |

| Response Time | Time taken for the valve to react | Critical control systems | Regular testing to ensure quick response |

1272 Speers Rd Unit 4

Oakville ON Canada L6L 2X4

©Copyright 2020 Gosco Valves. All rights reserved.