When it comes to plumbing, choosing the right components is crucial for ensuring efficiency and longevity in your system. One of the essential components that homeowners and professionals alike often overlook is the dual valve. According to plumbing expert John Smith, "Selecting the appropriate dual valve can significantly impact your plumbing system's overall performance and reduce the risk of leaks and failures." This statement highlights the importance of understanding the unique functions and benefits of different dual valve options available in the market.

Dual valves serve a pivotal role in managing water flow in various systems, whether for residential or commercial use. They can regulate and isolate water supply, which provides users with greater control and enhances the safety of plumbing systems. As we delve deeper into the nuances of selecting the right dual valve, we'll discuss key factors such as material, pressure ratings, and functionality. By equipping yourself with this knowledge, you can make an informed decision that meets your specific plumbing needs while optimizing performance and reliability.

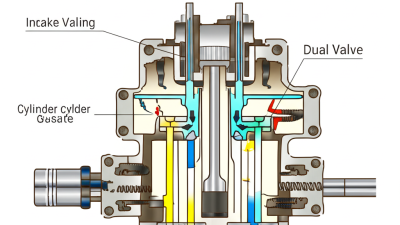

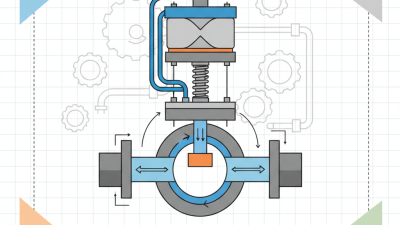

Understanding dual valves is essential for anyone dealing with plumbing systems. These components play a crucial role in regulating the flow of water, ensuring that systems operate efficiently and safely. A dual valve typically allows for the control of two different water sources or lines, making it a versatile choice for installations where managing multiple flows is necessary. Their design usually includes two separate handles or controls, enabling users to direct water as needed.

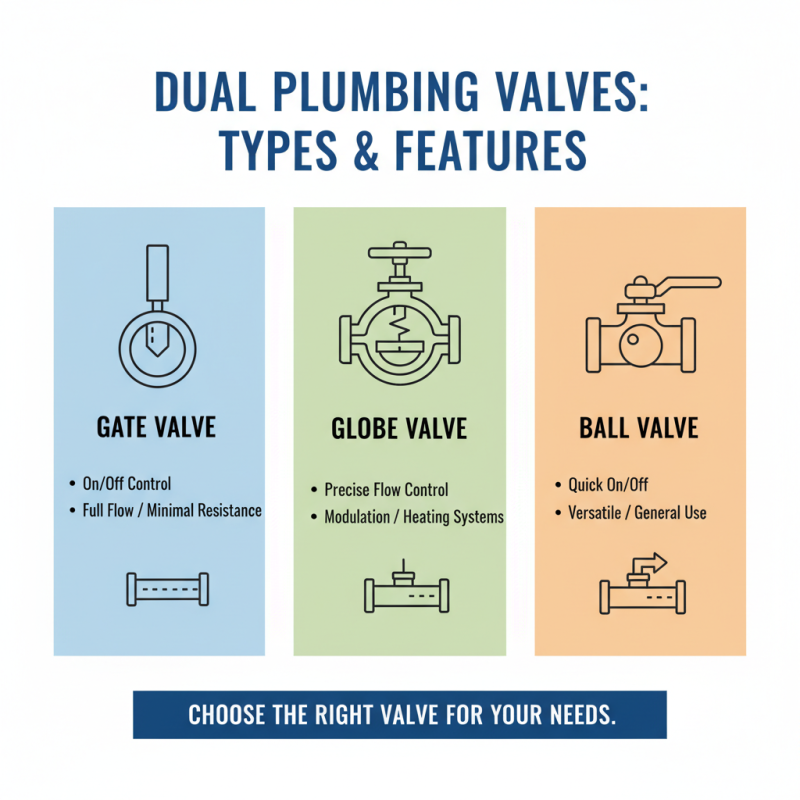

When selecting the right dual valve, it is important to consider the specific requirements of your plumbing system. Factors such as the medium being transported, pressure levels, and compatibility with existing pipe materials should all influence your choice. Additionally, the valve's size and type—whether it is a gate, globe, or ball valve—can significantly affect performance. Understanding these basics ensures that your plumbing system operates efficiently, minimizes leaks, and prolongs the lifespan of the entire setup.

When selecting a dual valve for your plumbing needs, it's essential to first identify your specific requirements. Understanding the flow rate, pressure requirements, and the intended use of the dual valve are crucial steps. According to a report by the Plumbing Manufacturers International (PMI), approximately 20% of plumbing installations fail to meet optimal performance due to improper valve selection. This emphasizes the importance of accurately assessing your plumbing system before making a decision.

Additionally, different environments—residential, commercial, or industrial—can dictate the specifications needed from a dual valve. For instance, the American Society of Plumbing Engineers (ASPE) suggests that residential plumbing systems typically require valves that can handle lower pressure ratings compared to industrial systems, which may need valves capable of withstanding higher pressures and flow rates.

Furthermore, considering materials such as brass or plastic can also have a significant impact on the valve's performance and lifespan, further exemplifying the critical nature of distinguishing your plumbing needs accurately before proceeding with a purchase.

When selecting a dual valve for plumbing needs, understanding the types and their features is essential. The prevalent types of dual valves include the gate valve, globe valve, and ball valve, each designed for specific applications. Gate valves are perfect for on-off control, providing minimal resistance when fully opened. They are commonly used in main lines where full flow is required. In contrast, globe valves offer more precise flow control due to their design, making them suitable for applications where adjusting the water flow is critical, such as in heating systems.

Ball valves, known for their quick operation and durability, are ideal for situations requiring frequent on-off activities. Their spherical disc design allows for a tight seal and minimal leakage. Additionally, dual valves with multiple ports can enable the diversion of water flow to different areas, enhancing flexibility in plumbing systems. It is crucial to consider the specific operating pressure and temperature ratings of each valve type to ensure compatibility with your plumbing setup. By comprehensively assessing these features and applications, one can make an informed choice that best meets their plumbing needs.

When selecting a dual valve for your plumbing needs, several factors play a crucial role in ensuring efficiency and functionality. First, consider the material of the valve. Brass, stainless steel, and plastic are common options, each with distinct advantages. Brass valves are durable and resistant to corrosion, while stainless steel offers enhanced longevity and resistance to high pressure. Plastic valves, on the other hand, are lightweight and cost-effective, although they may not handle extreme temperatures as well as their metal counterparts.

Another essential factor is the valve's size and compatibility with your existing plumbing. A valve that does not match the pipe size may lead to inefficient flow and potential leaks. Ensure that you have accurate measurements before making a purchase. Additionally, check the pressure rating of the valve; it should be suitable for the specific requirements of your plumbing system to avoid failures.

*Tip: Always consult with a plumbing professional if you're unsure about compatibility or sizing before making a decision. This can save you time and prevent costly mistakes.*

Moreover, think about the valve's functionality—whether it will be used for regulating flow, shutting off water supply, or both. For efficiency, look for valves with clear indicators for open and closed positions, as well as easy-to-operate handles.

*Tip: Consider valves that have a low leakage rate and are designed for quick maintenance, which can greatly extend the life of your plumbing system.*

| Factor | Description | Importance Level |

|---|---|---|

| Type of Fluid | Determine if the valve will handle water, gas, or chemicals. | High |

| Pressure Rating | Ensure the valve can withstand the operational pressure of your system. | Critical |

| Size and Compatibility | Check if the valve size matches your piping system specifications. | High |

| Material Composition | Consider corrosion resistance and durability based on environment. | Medium |

| Actuation Type | Decide between manual, electric, or pneumatic actuators. | High |

| Flow Rate | Ensure the valve can accommodate the necessary flow rate for your application. | High |

| Regulatory Standards | Check compliance with local plumbing codes and international standards. | Critical |

When installing dual valves in plumbing systems, proper orientation and positioning are crucial for optimal functionality. Begin by ensuring that the valve is installed in line with the water flow direction, typically indicated by arrows on the valve body. This alignment minimizes resistance and potential leaks. Additionally, position the valve in a location that allows for easy access, making future repairs or adjustments convenient. It's also essential to consider the space around the valve; adequate clearance ensures that you can operate or replace the valve without obstruction.

When it comes to sealing and securing the connections, use appropriate thread sealants or Teflon tape to prevent leaks. Make sure to tighten fittings progressively and avoid over-torquing, as this can lead to damage. After installation, it’s wise to conduct a thorough leak test. Turn on the water supply slowly to inspect for any signs of leakage around the valve and connections. If leaks are detected, address them promptly to avoid water damage and ensure the integrity of your plumbing system. Regular maintenance checks can also extend the life of your dual valve, ensuring it operates efficiently.

1272 Speers Rd Unit 4

Oakville ON Canada L6L 2X4

©Copyright 2020 Gosco Valves. All rights reserved.