When selecting the right rotary valves, many factors come into play. These valves play a crucial role in various industries. They regulate the flow of materials like powders and granules. Choosing the perfect one can enhance efficiency and productivity.

Consider the material of the rotary valves. Different materials suit specific applications. For example, stainless steel is durable and resistant to corrosion. However, it may be overkill for lighter-duty tasks. This decision requires careful thought.

Next, think about the valve’s size and design. A valve that is too small may restrict flow. Conversely, one that is too large can lead to inefficiency. Always align the valve's specifications with your needs. Recognizing the specific application is vital. Reflect on past experiences and learn from them for better decision-making. Selecting the right rotary valves is not just a choice; it’s an ongoing process of evaluation and improvement.

Rotary valves play a crucial role in various industrial applications. They regulate the flow of materials, whether solid or liquid. Understanding their functionality can greatly improve efficiency in manufacturing processes. Depending on the application, the design and operation of rotary valves can vary significantly.

Different industries utilize these valves for distinct purposes. In food processing, precision is key. A small error can lead to contamination. In chemical processing, durability matters. Valves must withstand corrosive substances. Each application has unique requirements that should not be overlooked.

Selecting the right rotary valve requires careful consideration. Mistakes can be costly. A valve that is too small may restrict flow, while one that is too large might lead to leaks. Assessing the material's properties is vital. Are they abrasive or sticky? Analyzing the flow rate is equally important. Sometimes, consulting with experts can reveal what aspects are often underestimated. Balancing cost and performance is another area worth reflecting on.

When selecting the right rotary valves, it's crucial to identify your specific needs. Understanding your application is key. For example, you need to know the pressure range, temperature, and the type of material being handled. Data shows that improper selection can lead to inefficiencies, affecting processing time and costs.

Tip: Always assess the compatibility of the valve with your material. This can prevent leaks and unexpected failures.

Consider the performance specifications required in your operations. For instance, certain pneumatic conveying systems operate optimally with specific valve designs. Industry reports indicate that nearly 30% of failures result from mismatches in duty cycles.

Tip: Investigate the maintenance needs of various rotary valve types. Knowing this can save you time and money in the long run.

In some cases, the cost may seem attractive, but further analysis might reveal hidden operational costs. Be cautious about compromising on quality for price. An unsuitable valve can lead to more frequent breakdowns.

| Application | Material Compatibility | Pressure Rating | Temperature Range | Type of Actuation |

|---|---|---|---|---|

| Food Processing | Stainless Steel | 150 psi | -10°C to 60°C | Pneumatic |

| Chemical Processing | PVC | 200 psi | 0°C to 80°C | Electric |

| Pharmaceuticals | 316L Stainless Steel | 250 psi | -20°C to 70°C | Manual |

| Water Treatment | Bronze | 125 psi | -5°C to 40°C | Hydraulic |

When evaluating different types of rotary valves, it's essential to consider their specific applications. These valves come in various designs, each tailored for distinct functions. For example, some are ideal for controlling air flow, while others manage granular materials. It’s crucial to assess the mediums you'll be working with. Will you be handling abrasive materials? That requires a durable build to ensure longevity.

Understanding the size and pressure rating of your application is vital, too. Some valves operate efficiently under low pressure, while others need to withstand high pressure and flow conditions. Keep in mind that a valve’s performance can vary significantly based on its design, such as compact or segmented styles. Sometimes, a more complex design may not always be the best choice. Simplicity can lead to easier maintenance and reliability.

Don’t overlook the installation requirements. Some rotary valves need more space than others. It's easy to underestimate the importance of a proper fit in the overall system. With the right selection process, you can avoid costly mistakes later on. The wrong choice might lead to operational inefficiencies. Take your time to ensure you are aware of every detail before making a decision.

Selecting the right rotary valves requires careful consideration of several factors. Size is crucial. Measure your system’s dimensions accurately. A valve too large or small can disrupt flow efficiency. Similarly, the pressure rating must match your process. High-pressure environments need stronger valves.

Material choice cannot be overlooked. Common options include aluminum and stainless steel. Each material has its pros and cons. For example, aluminum is lighter but may corrode faster in certain environments. Think about the materials you handle as well. Compatibility is vital to prevent failure.

Consider the valve’s operating mechanism. Some are manual, while others are pneumatic or electric. Manual valves provide more control, but automation may enhance efficiency. However, automating can introduce complexity. Think about maintenance too. Regular checks are essential to prevent costly downtimes. Balancing all these factors may seem daunting. Yet, thoughtful reflection will guide your choice.

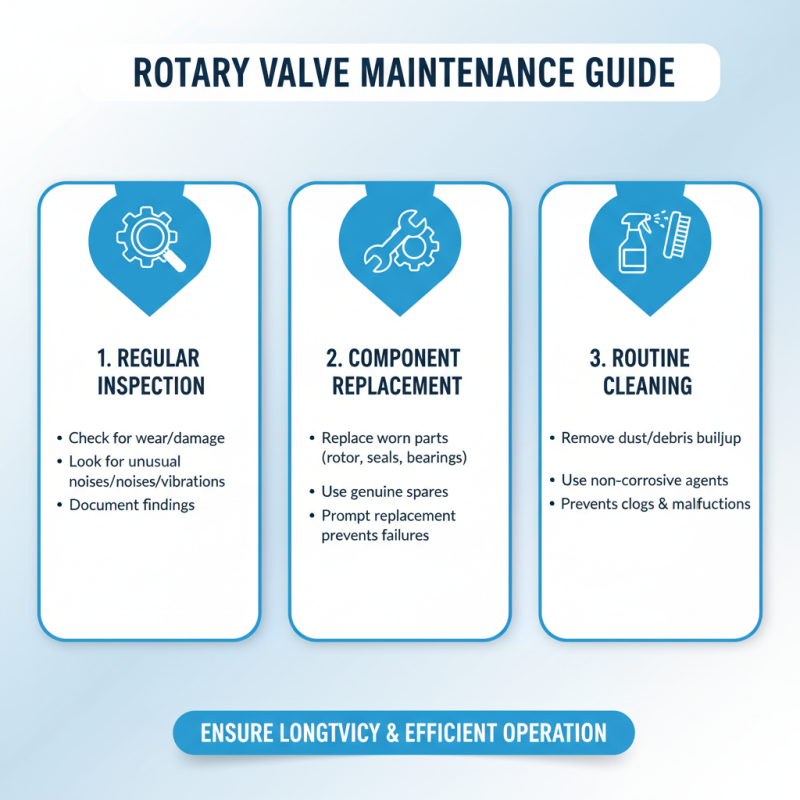

Rotary valves play a critical role in various industries. Proper maintenance ensures their longevity and efficient operation. Regular inspection is essential. Check for signs of wear or damage. Replace worn components promptly to avoid system failures. A routine cleaning regimen is also necessary. Dust and debris can clog the valve, causing it to malfunction. Use suitable cleaning agents to prevent corrosion.

Lubrication is a key factor in maintaining rotary valves. Applying the right lubricant reduces friction. This helps the valves operate smoothly. However, over-lubrication can attract dirt. Regularly assess the lubrication levels to maintain a balance. Additionally, monitor the operating conditions. Extreme temperatures or pressures can impact the valve’s performance. Ensure the settings are optimal for the valve type.

It’s crucial to train staff on proper handling. Misuse can lead to premature wear. Operators should follow guidelines carefully. Documenting maintenance activities provides a clear history. This can help identify recurring issues. Sometimes, maintenance routines need revisiting. An evaluation may reveal that some practices are no longer effective. Consistent review can significantly improve reliability.

1272 Speers Rd Unit 4

Oakville ON Canada L6L 2X4

©Copyright 2020 Gosco Valves. All rights reserved.