Choosing the right valve handle for your plumbing needs is crucial to ensuring the efficiency and effectiveness of your plumbing system. According to industry expert John Smith, a plumbing engineer with over 20 years of experience, "The right valve handle not only enhances usability but also significantly impacts the longevity of your plumbing fixtures." This highlights the importance of selecting a valve handle that matches both the technical requirements of your plumbing system and your personal preferences for functionality and ease of use.

In the world of plumbing, where precision and reliability are paramount, understanding the different types of valve handles available is essential. From ergonomic designs to material considerations, each factor plays a significant role in how a valve handle performs. Whether you are upgrading existing fixtures or performing a complete renovation, making an informed choice can lead to better system performance and reduced maintenance issues in the long run. By delving into the intricacies of valve handles, you can better equip yourself to make the right decisions tailored to your specific plumbing needs.

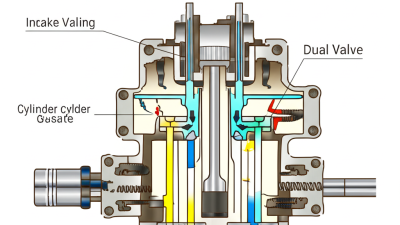

When it comes to plumbing, selecting the right valve handle is crucial for both functionality and aesthetics. Valve handles come in various types, each suited for different applications. Common types include lever handles, round handles, and knob handles. Lever handles are generally preferred for their ease of use, especially in situations where quick adjustments are necessary. Round handles tend to be more traditional, often found in older plumbing systems, while knob handles provide a classic look but may require a bit more effort to operate.

Another significant aspect to consider is the material of the valve handle. Metal handles, such as those made from brass or stainless steel, offer durability and resistance to corrosion. On the other hand, plastic handles can be lightweight and cost-effective but may not withstand high temperatures or aggressive chemicals. The choice of handle should align not only with the type of valve it operates but also with the overall style of your plumbing fixtures. By understanding the different types of valve handles available, homeowners can make informed decisions that ensure both the efficiency and longevity of their plumbing systems.

| Type of Valve Handle | Material | Common Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Lever Handle | Metal or Plastic | Shower Valves, Sink Faucets | Easy to operate | Can be prone to damage |

| Round Handle | Brass or Chrome | Water Supply Systems | Durable and long lasting | Less ergonomic |

| Wheel Handle | Plastic or Metal | Old Plumbing Systems | Simple design, easy to use | Slow operation |

| Push/Pull Handle | Plastic | Shower and Bath Valves | Compact and clean design | Potential for wear over time |

| Single Handle | Metal or Composite | Kitchen and Bathroom Faucets | Instant control of both flow and temperature | Can be complex to install |

When selecting a valve handle for your plumbing needs, one critical aspect to consider is the material used in its construction. Different materials offer varying levels of durability and performance, impacting the overall functionality of your plumbing system. Common materials include plastic, metal, and composites. Each has its unique properties: plastic handles are lightweight and resistant to corrosion but may not hold up under extreme pressure or temperature. Conversely, metal handles, often made from brass or stainless steel, provide enhanced strength and resilience, making them suitable for high-pressure applications.

Another factor to evaluate is how the material impacts the handle's grip and usability. A well-designed handle should offer a comfortable grip and allow for easy turning, especially in situations that require frequent adjustments. For instance, rubberized or coated metal handles can improve grip, reducing the risk of slippage, particularly in wet environments. Furthermore, the thermal conductivity of the material is essential to consider; if a valve is near a heat source, choosing a handle that remains cool to the touch can enhance safety and ease of operation. Ultimately, evaluating these material options will ensure that you choose a valve handle that meets your specific plumbing requirements while standing the test of time.

This chart compares the durability ratings of different valve handle materials. Brass shows the highest durability, followed by stainless steel, bronze, and plastic.

When selecting the right valve handle for plumbing applications, sizing plays a critical role in ensuring proper function and efficiency. The first consideration is the diameter of the valve stem, which should match the handle's fitting to maintain a secure connection. For example, larger stems may require handles with a wider mounting hole, making it essential to measure accurately before making a choice. Additionally, the length of the handle should be considered; longer handles often offer greater leverage, making it easier to operate the valve, especially in high-pressure systems.

Another important aspect is the type of application the valve handle is intended for. Residential plumbing often utilizes smaller, less robust handles, while industrial settings may necessitate handles that can withstand heavy use and provide enhanced durability. Different materials, such as plastic or metal, also influence the size and strength of the handle. In some cases, ergonomic designs can improve grip and reduce strain, making them suitable for handles in frequently used valves. Proper sizing and selection based on the specific application are crucial not only for functionality but also for safety in plumbing systems.

When selecting a valve handle for your plumbing needs, it’s essential to identify the various styles that are available to ensure both functionality and ease of use. Different handle types cater to different requirements, with considerations such as grip comfort and the specific application of the valve playing crucial roles. For instance, a lever handle is often the preferred choice for environments requiring quick and effortless operation, as it allows for easy adjustments with minimal force. Alternatively, round or oval handles may provide a classic look but can be less ergonomic, making them less suitable for frequent use.

Another critical factor in choosing a valve handle is the material from which it is made. Handles crafted from durable materials like brass or stainless steel offer longevity and can withstand the rigors of regular use, especially in high-pressure systems. Additionally, considering the size and shape of the handle can enhance usability; larger handles may provide better leverage, while textured grips can offer improved control even in wet conditions. Each of these elements contributes to a handle’s overall effectiveness, ensuring you can operate your plumbing systems without unnecessary strain.

When it comes to maintaining valve handles, regular upkeep is key to ensuring their longevity and performance. A well-maintained valve handle can prevent leaks and ensure smooth operation, which is essential for effective plumbing. Start by periodically inspecting your valve handles for any signs of wear, such as cracks or corrosion. If you notice anything amiss, address the issue promptly to prevent further damage.

Tips to extend the lifespan of your valve handles include keeping them clean and lubricated. Regularly wipe down the handles with a mild detergent to remove any accumulated dirt and grime. Additionally, apply a silicone lubricant to moving parts to reduce friction and prevent rust formation. This simple routine can help your valve handles function smoothly and efficiently.

Another important aspect of valve handle maintenance is ensuring they are properly tightened. Loose handles can lead to unnecessary stress on the valve components, causing potential leaks or operational failures. Make it a habit to check the tightness of your valve handles during your routine inspections. By implementing these practices, you can enhance the performance and durability of your plumbing fixtures.

1272 Speers Rd Unit 4

Oakville ON Canada L6L 2X4

©Copyright 2020 Gosco Valves. All rights reserved.