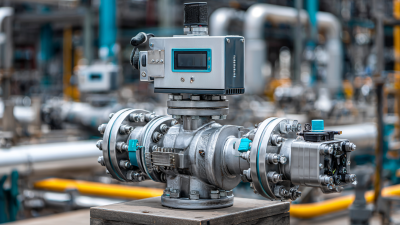

High temperature valves are integral components in industries that operate under extreme thermal conditions, such as petrochemicals, power generation, and aerospace. According to a recent report by MarketsandMarkets, the high temperature valves market is projected to reach $6.2 billion by 2026, growing at a CAGR of 5.2% during the forecast period. This growth can be attributed to the increasing demand for energy-efficient technologies and the rise in oil and gas exploration activities. As industries evolve, the need for reliable and high-performance valves becomes paramount, necessitating innovative designs that can withstand demanding environments.

Renowned industry expert Dr. Emily Carson, a leading authority on valve technologies, emphasizes the importance of selecting the right high temperature valves for optimal system performance. She states, "The longevity and efficiency of high temperature applications highly depend on the quality and suitability of the valves employed. Selecting a valve that can endure extreme thermal and pressure conditions is crucial for maintaining operational reliability and safety." This insight underscores the critical role that high temperature valves play in ensuring processes run smoothly in even the harshest conditions. In this article, we will delve into the top 10 high temperature valves that exemplify optimal performance and reliability in industrial applications.

High temperature valves play a crucial role in various industrial applications, particularly in sectors where extreme conditions are prevalent, such as oil and gas, power generation, and chemical processing. According to a report by MarketsandMarkets, the global high temperature valve market is projected to reach $3.4 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.4% from 2020. This growth underscores the importance of high temperature valves in ensuring operational efficiency and safety in environments that frequently exceed 300°C (572°F).

The significance of high temperature valves extends beyond mere functionality; they are essential for maintaining system integrity and preventing failures. Notably, these valves are engineered to withstand harsh conditions, including pressure fluctuations and corrosive environments. A study by Research and Markets highlights that up to 30% of maintenance costs in industrial operations are attributed to valve failures, emphasizing the need for reliable high temperature solutions. With applications ranging from steam control to chemical reactors, these valves ensure that processes remain efficient while minimizing the risk of unplanned downtime and enhancing longevity in extreme operational scenarios.

When selecting high temperature valves, several critical considerations come into play to ensure optimal performance and reliability in demanding applications. First and foremost, understanding the operating temperature range of the valve is essential. High temperature valves must be constructed from materials that can withstand extreme heat without compromising integrity. Common materials include stainless steel and specialized alloys designed to resist thermal degradation.

Another key factor is the valve design itself. Different types of valves, such as ball, gate, or globe valves, have varying capabilities and flow characteristics. It is vital to choose a design that aligns with the specific application needs, including pressure requirements and the type of fluid being controlled. Additionally, considering the valve's sealing mechanism is crucial; a robust seal material can prevent leaks and ensure longevity even under high thermal stress.

**Tips:** Always consult with experts or reference technical specifications to confirm that the selected valve meets the application’s demands. Additionally, evaluating past performance data or case studies can provide valuable insights into how specific valves perform in high temperature environments, guiding you toward a more informed decision. Lastly, regular maintenance and inspections are essential to identify wear and tear that could affect valve performance before it leads to failures.

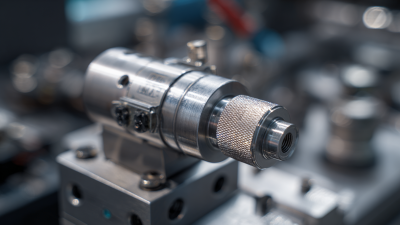

When it comes to high temperature valve manufacturing, the choice of materials is crucial for ensuring optimal performance and reliability. Valves that operate under extreme temperatures must be made from materials that can withstand thermal expansion, corrosion, and other mechanical stresses. Some of the top materials used include stainless steel, titanium, and high-performance alloys. According to a recent industry report by the Valves Manufacturing Association, stainless steel grades like 316 and 310 exhibit excellent resistance to oxidation and can operate efficiently at temperatures exceeding 1000°F (537°C).

Moreover, utilizing materials with high thermal stability is essential. For example, ceramic and special composites are increasingly being used in high temperature applications, promising longevity and reliability. A study published in the Journal of Material Science highlights that these materials maintain structural integrity better than traditional metals under prolonged thermal exposure. This is particularly significant in industries such as petrochemical and power generation, where valve failure can lead to downtime and increased operational costs.

**Tips:** When selecting materials for high temperature valves, consider the specific operating conditions, including pressure and fluid type. Additionally, always consult material datasheets and relevant standards to ensure compliance and optimal performance. Regular maintenance and inspections are also vital for assessing material degradation over time.

When selecting high-temperature valves for industrial applications, it is essential to consider several key performance features that ensure optimal functionality and reliability. One of the most critical aspects is the material composition of the valve. For instance, valves made from high-grade alloys or special ceramics can withstand extreme temperatures, often reaching up to 800°F (427°C) without deformation. According to a report by the International Journal of Thermodynamics, materials with strong thermal resistance not only ensure longevity but also minimize downtime, contributing to impressive lifecycle savings.

Another important feature is the valve's sealing technology. High-temperature applications often experience thermal expansion and contraction, which can compromise seal integrity. Utilizing advanced sealing materials, such as Teflon or silicone rubber, can significantly enhance a valve’s ability to maintain a leak-proof seal under extreme conditions. A study by the Valve Manufacturers Association highlights that effective sealing can prevent a 20% energy loss, emphasizing its importance in both performance and efficiency.

Tips: When assessing high-temperature valves, always verify their certifications and compliance with industry standards. Additionally, consider the valve design; a compact and lightweight design can not only facilitate easier installation but also improve the system's overall efficiency. Regular maintenance checks on these valves are also recommended to ensure their performance remains optimal over time.

When it comes to high temperature valves, selecting the right one is crucial for ensuring optimal performance and reliability in industrial applications. Various leading brands on the market have developed innovative designs tailored to withstand extreme conditions while maintaining efficiency. These models typically feature robust materials like stainless steel and special alloys that can endure high pressure and temperature variations, making them ideal for sectors such as oil and gas, power generation, and chemical processing.

In addition to material quality, key factors in choosing high temperature valves include their sealing mechanism and actuation methods. Advanced sealing technologies provide enhanced leak protection, ensuring safety and compliance with industry standards. Furthermore, options for manual or automated actuation allow for versatility in operation, catering to different application needs. By focusing on these critical features, industries can ensure they select from the leading models that support reliable and efficient operation, thereby maximizing productivity in their processes.

1272 Speers Rd Unit 4

Oakville ON Canada L6L 2X4

©Copyright 2020 Gosco Valves. All rights reserved.