The hydraulic control valve plays a pivotal role in the fluid power industry, serving as a critical component in various hydraulic systems to manage the flow and pressure of hydraulic fluids. According to industry reports, the global hydraulic components market is anticipated to reach USD 52.14 billion by 2026, indicating a growing demand for efficient hydraulic solutions. As industries such as manufacturing, construction, and automotive increasingly rely on hydraulic systems for their operations, understanding the mechanics and functionality of hydraulic control valves becomes essential.

These valves precisely regulate the flow of hydraulic fluid, facilitating the smooth operation of machinery and equipment. By adjusting the fluid pressure and directing its flow, hydraulic control valves enhance the performance and efficiency of hydraulic systems. Reports suggest that the market for hydraulic valves is expected to grow at a CAGR of around 5.4% from 2021 to 2026, driven by advancements in technology and the need for more automated and precise control in hydraulic systems. In this context, exploring the design, function, and benefits of hydraulic control valves not only illuminates their significance but also highlights the advancements that continue to shape the future of hydraulic technology.

Hydraulic control valves are essential components in hydraulic systems, serving as the brains that direct fluid flow and pressure. Their primary purpose is to control the actuation of hydraulic devices, ensuring that systems operate smoothly and efficiently. These valves can regulate different aspects of hydraulic fluid, such as flow rate and direction, allowing for precise control over machinery and equipment. By adjusting the flow, hydraulic control valves play a crucial role in enhancing performance and safety in various applications, from industrial machinery to sophisticated automotive systems.

One of the most significant advantages of hydraulic control valves is their ability to maintain system pressure. This is vital in applications where excessive pressure could lead to equipment failure or safety hazards. Furthermore, these valves help in reducing energy consumption by optimizing the hydraulic fluid flow, which ultimately leads to cost savings and improved operational efficiency.

Tips: When working with hydraulic control valves, always ensure proper maintenance and inspection to prevent leaks and mechanical failure. Additionally, familiarize yourself with the valve specifications and operational guidelines to maximize their effectiveness in your hydraulic system. Understanding the characteristics of different valve types can also enhance your ability to select the right one for your specific application, leading to better performance and reliability.

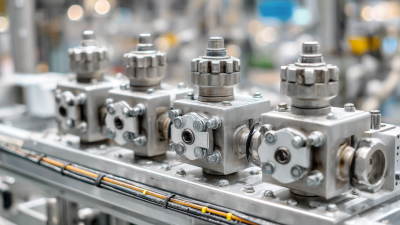

Hydraulic control valves are essential components in hydraulic systems, and understanding their key elements is crucial for effective operation. One of the primary components of a hydraulic control valve is the actuator, which enables the valve to open or close in response to input signals. Actuators can be mechanical, pneumatic, or hydraulic, depending on the design of the system. They ensure precise control over fluid flow and pressure, which ultimately affects the performance of the entire hydraulic circuit.

Another vital component is the valve body, which houses the internal mechanisms and fluid passages. The configuration of the valve body determines how fluid flows through the system, whether it’s a directional control valve that redirects flow, a pressure relief valve that regulates excess pressure, or a flow control valve that manages flow rate. Additionally, seals and glands are crucial for maintaining system integrity by preventing leakage and ensuring pressure retention. Understanding these components and their functions helps in the effective design and maintenance of hydraulic systems, ensuring reliability and efficiency in their operation.

| Component | Function | Material |

|---|---|---|

| Body | Houses other components and provides structure | Cast iron, aluminum, or steel |

| Spool | Controls fluid flow paths | Steel or hardened material |

| actuator | Drives the spool to change flow direction or volume | Hydraulic fluid, pneumatic system |

| Inlet/Outlet Ports | Connect to hydraulic fluid supply and return lines | Metal or composite material |

| Check Valve | Prevents backflow of hydraulic fluid | Brass or stainless steel |

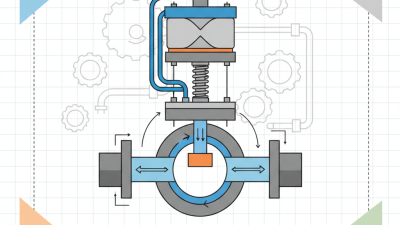

Hydraulic control valves are crucial components in hydraulic systems, managing the flow and direction of hydraulic fluid. Mechanically, these valves operate through a system of movable parts that respond to pressure changes and operator inputs. At their core, hydraulic control valves consist of a valve body, spool, and actuator. The valve body contains channels that direct fluid flow, while the spool, which is a cylindrical part that can slide within the valve body, determines the path that the fluid takes based on its position.

When an operator inputs a command, the actuator initiates movement of the spool, which shifts to open or close channels within the valve body. This action regulates the amount of fluid passing through, effectively controlling the speed and force of hydraulic actuators like cylinders and motors. The mechanical design allows for precise control over the hydraulic system, facilitating various functions such as lifting, steering, and braking in industrial and mobile applications. The interaction between the hydraulic fluid pressure and the mechanical components enables a responsive and efficient system, key to the performance of hydraulically driven machinery.

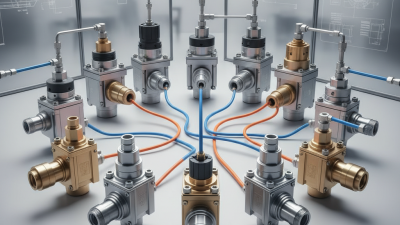

Hydraulic control valves play a crucial role in the efficient operation of hydraulic systems, and they come in various types, each tailored for specific applications. One common type is the directional control valve, which regulates the flow direction in a hydraulic circuit. These valves can be manually operated or controlled automatically based on system demands. They are widely used in hydraulic actuators, such as cranes and excavators, where changing the direction of hydraulic fluid is essential for movement.

Another prevalent type is the pressure control valve, which ensures that the system maintains optimal pressure levels. These valves can limit or release pressure, providing safety and preventing damage to hydraulic components. Pressure control valves find application in systems where load variations may lead to excessive pressure, such as in lifting equipment or hydraulic presses. Additionally, flow control valves manage the speed of hydraulic actuators by controlling the flow rate. This is vital in applications requiring precise movements, such as in robotics or automated manufacturing processes, ensuring smooth and efficient operation. Each type of valve contributes significantly to the functionality and safety of hydraulic systems, catering to a wide range of industrial needs.

Hydraulic control valves play a crucial role in the efficiency and safety of hydraulic systems. However, like any mechanical component, they can encounter common issues that may affect their performance. Leaks are one of the most prevalent problems, which can occur due to worn seals or improper installation. Regular inspection of the valve for signs of fluid leakage is essential. Additionally, internal wear from debris or degradation of valve components can lead to ineffective control and response times, thereby hindering the overall functionality of the hydraulic system.

To maintain hydraulic control valves, it is critical to establish a routine maintenance schedule that includes regular cleaning and inspection. Flushing the hydraulic fluid periodically helps remove contaminants that can cause wear and tear. Operators should also check for proper alignment and secure connections to prevent unwanted vibrations and stress on the valve. Lubrication of movable parts is important as well, as it reduces friction and prolongs the life of the valve. By adopting these maintenance practices, one can ensure that hydraulic control valves operate smoothly and effectively, thereby enhancing the reliability of the entire hydraulic system.

1272 Speers Rd Unit 4

Oakville ON Canada L6L 2X4

©Copyright 2020 Gosco Valves. All rights reserved.