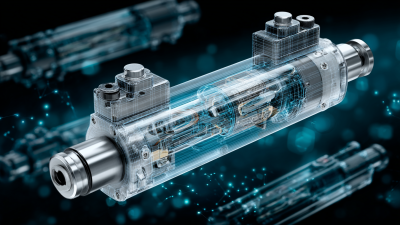

In the realm of hydraulic systems, the efficiency and performance of machinery heavily rely on the proper functioning of hydraulic control valves. These components serve a critical role in regulating the flow and pressure of hydraulic fluid, ensuring that mechanical systems operate smoothly and effectively. Understanding the various types of hydraulic control valves is essential not only for engineers and technicians but also for anyone involved in the design and implementation of hydraulic systems.

This article outlines the top 10 hydraulic control valve types you need to know, providing insights into their specific applications and advantages. By familiarizing yourself with these valve types, you can optimize the performance of your hydraulic systems, reduce downtime, and enhance the overall reliability of your equipment. Whether you are a seasoned professional or a newcomer to the field, grasping the nuances of hydraulic control valves is paramount for achieving optimal performance in any hydraulic application.

Hydraulic control valves play a crucial role in the efficiency and safety of hydraulic systems, governing the flow and pressure of hydraulic fluid. These valves are essential components in machinery and equipment, allowing operators to control movements precisely and respond to varying operational demands. Their importance cannot be overstated, as they ensure optimal performance by helping maintain the desired system pressure and flow rates, thereby enhancing the overall effectiveness of hydraulic applications.

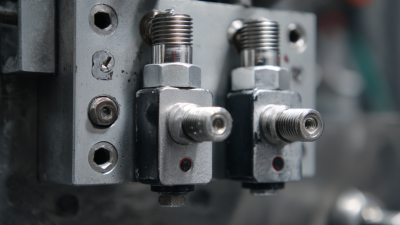

Understanding the different types of hydraulic control valves is vital for anyone involved in the design, maintenance, or operation of hydraulic systems. Each valve type, from proportional valves to relief valves, serves specific functions that cater to various needs, such as load handling, speed regulation, and system protection. The selection of the appropriate valve not only affects the performance of the hydraulic system but also impacts its longevity and reliability. Therefore, gaining insights into these valves' functions and characteristics is essential for achieving optimal hydraulic performance in industrial and mobile applications.

Hydraulic control valves play a crucial role in the efficient operation of hydraulic systems. Understanding the key types of hydraulic control valves is essential for optimizing performance across various applications. According to the International Journal of Fluid Mechanics Research, proper selection and classification of these valves can enhance system efficiency by up to 30%, reducing energy consumption and operational costs. Among the prominent types are directional control valves, pressure control valves, and flow control valves, each serving a distinct purpose within a hydraulic circuit.

Directional control valves are primarily responsible for controlling the flow path of hydraulic fluid within the system. They can be further classified into various types, such as spool valves and poppet valves, which cater to different operational requirements. Pressure control valves, on the other hand, are designed to maintain a desired pressure level within the system, protecting components from damage due to surges. Meanwhile, flow control valves regulate the speed of actuators by adjusting fluid flow rates, allowing for precise control of movement. As reported by the Hydraulic Institute, the right combination of these valves can improve efficiency and reliability, thereby maximizing the performance of hydraulic machinery across diverse industries.

| Valve Type | Function | Application | Advantages | Limitations |

|---|---|---|---|---|

| Directional Control Valve | Controls the direction of fluid flow | Excavators, hydraulic lifts | Versatile, reliable | Complex design, possible leakage |

| Pressure Control Valve | Regulates system pressure | Pressure relief in hydraulic systems | Protects equipment, prevents overpressure | Requires accurate calibration |

| Flow Control Valve | Controls the flow rate of fluid | Cylinders, motors | Improves speed control | Limited to controlling speed only |

| Check Valve | Allows flow in one direction only | Prevents backflow in hydraulic circuits | Simple, effective | No control over flow rate |

| Solenoid Valve | Electrically actuated valve | Automation, machinery | Quick response, easy automation | Requires power supply |

| Proportional Valve | Controls flow and pressure proportionally | Robotics, CNC machines | High precision | More complex and costly |

| Sequence Valve | Controls the sequence of operations | Multi-actuator systems | Ensures orderly operation | Limited by sequence design |

| Throttling Valve | Controls flow and pressure via resistance | Speed control in hydraulic machines | Simple design | Can reduce system efficiency |

| Ball Valve | Allows or blocks fluid flow | On/off control | Minimal pressure drop | Not suitable for throttling |

| Multi-Functional Valve | Combines several functions into one | Compact hydraulic systems | Space-saving, flexible | Complex design may lead to maintenance challenges |

Hydraulic control valves are critical components in hydraulic systems, influencing overall performance and efficiency. Among the ten main types, such as directional control, pressure relief, and flow control valves, each serves a unique function while contributing to optimal functioning. For instance, directional control valves are essential in determining the path of fluid flow, often guided by spool configurations; according to a report by MarketsandMarkets, the market for these valves is projected to grow significantly, driven by advances in automation and fluid dynamics.

Tips: When selecting a hydraulic control valve, consider factors such as flow rate, pressure requirements, and compatibility with the fluid used in your system. Regular maintenance, including inspection of seals and actuation mechanisms, can enhance the longevity and reliability of your valves.

Moreover, pressure relief valves play an indispensable role in protecting hydraulic systems from excessive pressure, preventing equipment failure. Recent studies indicate that integrating smart technology with these valves can improve response times and adapt to varying load conditions, which can lead to a reduction in energy consumption by up to 20%. Adopting such innovations can significantly enhance the overall performance and sustainability of hydraulic operations.

When discussing hydraulic control valves, understanding the factors that impact their performance is crucial for ensuring optimal functionality. One key element is the fluid viscosity, which can drastically affect flow rates and valve responsiveness. Higher viscosity fluids require more force to operate the valve, potentially leading to delays in response time. Regular monitoring of fluid properties can help maintain optimal performance levels.

Tip: Always choose hydraulic oil that meets the manufacturer's specifications to ensure compatibility and maximum efficiency.

Another significant factor is the valve design and configuration. Different applications require specific valve types, such as proportional, relief, or check valves, which are designed for distinct functionalities. Proper selection is essential, as it will influence system response and overall performance.

Tip: Consult with a hydraulic systems expert when selecting valve types for your application to ensure you meet the demands of your hydraulic system effectively.

Moreover, the maintenance schedule and practices play a vital role in performance. Regular inspection and timely replacement of worn parts can prevent system failures and prolong the service life of hydraulic control valves.

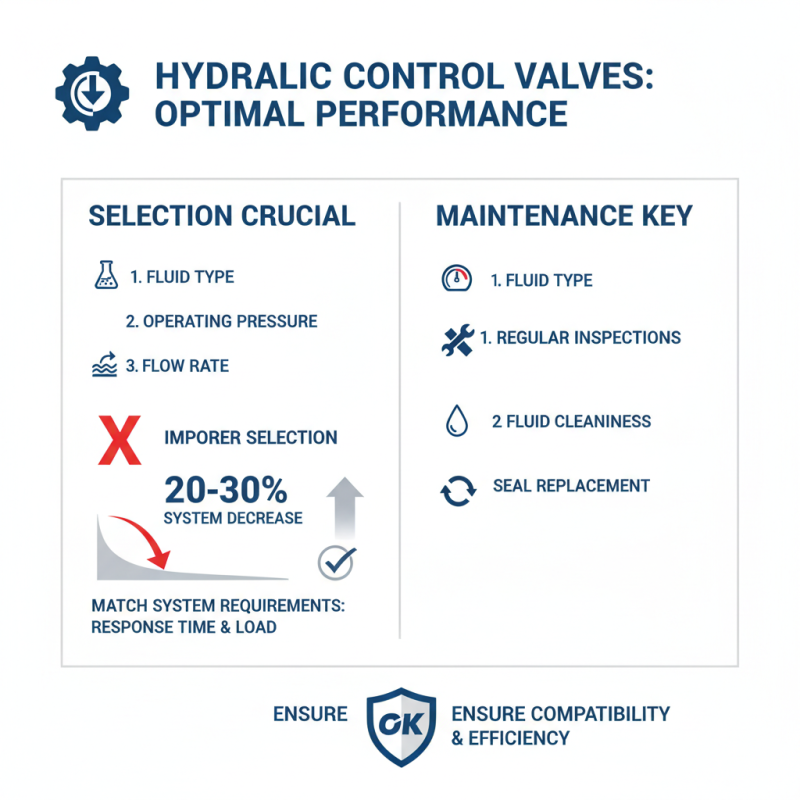

Selecting and maintaining hydraulic control valves is crucial for ensuring their optimal performance in various applications. When choosing a hydraulic control valve, it’s essential to consider factors such as the type of fluid, operating pressure, and flow rate to ensure compatibility and efficiency. According to industry reports, improper selection can lead to a 20-30% decrease in system performance, highlighting the importance of careful consideration during the selection process. Valves should match the specific requirements of the system, including response times and load conditions, to function effectively.

Maintenance practices play a significant role in the longevity and reliability of hydraulic control valves. Regular inspection and servicing can prevent unexpected failures and costly downtime. Industry standards recommend a comprehensive maintenance schedule that includes checking for leaks, measuring operating temperatures, and ensuring that seals and fittings are in good condition. Data from the Hydraulic Institute suggests that up to 75% of hydraulic system failures can be traced back to inadequate maintenance practices. By adhering to best practices in both selection and maintenance, operators can enhance the efficiency of their hydraulic systems and minimize operational risks.

1272 Speers Rd Unit 4

Oakville ON Canada L6L 2X4

©Copyright 2020 Gosco Valves. All rights reserved.