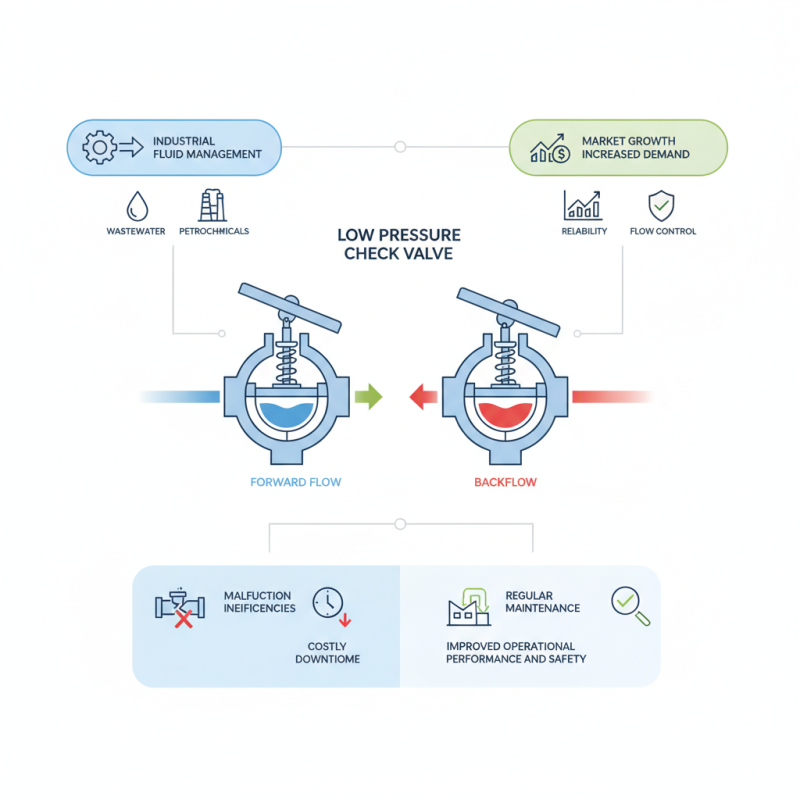

In industrial applications, the low pressure check valve plays a crucial role in fluid management. According to a report by Global Industry Analysts, the market for check valves is expected to grow significantly, driven by increased demand for effective flow control. Low pressure check valves are designed to prevent backflow, ensuring smooth operation in piping systems.

The mechanism is relatively simple yet vital. These valves utilize a spring-loaded disc, allowing flow in one direction while blocking reverse movement. In industries such as wastewater management and petrochemicals, reliability is paramount. A malfunction can lead to operational inefficiencies and costly downtime. Despite their simplicity, low pressure check valves sometimes fail to maintain proper sealing, leading to backflow issues.

Moreover, regular maintenance of these valves is often overlooked. Companies might focus on larger equipment while neglecting this essential component. This oversight can result in unexpected failures. Understanding the importance of a low pressure check valve can enhance system reliability, ultimately improving operational performance and safety.

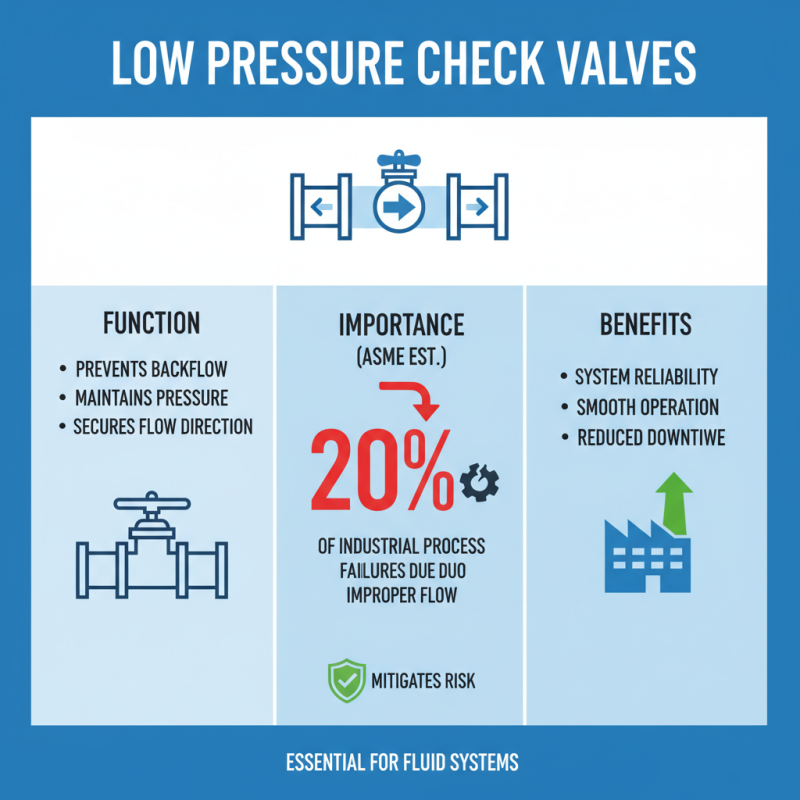

A low pressure check valve is a crucial component in various fluid systems. It allows fluid to flow in one direction while preventing backflow. This function is vital in applications where maintaining a steady flow is essential. When pressure is low, the valve remains closed, preventing unwanted fluid movement.

The design of a low pressure check valve is often simple yet effective. It typically consists of a disc or ball that seals against a seat. When the fluid pressure increases, it forces the disc or ball open, allowing flow. Once the pressure drops, the valve automatically closes, stopping any reverse flow. This simple mechanism can help reduce wear on pumps and minimize energy loss.

However, like any mechanical device, low pressure check valves can have shortcomings. They may require periodic maintenance to function properly. If debris accumulates, it could hinder the valve’s operation. Sometimes, they may not close properly, leading to leaks. It's essential to monitor these valves regularly to ensure they perform as intended. Making adjustments to the system can often address these challenges.

| Feature | Description |

|---|---|

| Function | Prevents backflow in low pressure systems |

| Applications | Water supply, HVAC systems, drainage systems |

| Material | Plastic, brass, stainless steel |

| Pressure Rating | Typically below 150 PSI |

| Activation | Automatically opens and closes based on pressure differences |

| Maintenance | Periodic inspection recommended for debris and wear |

A low pressure check valve is critical in fluid systems. Understanding its key components helps in grasping its function. The valve often features a disc, spring, and body. The disc seals against the flow when pressure is low. The spring facilitates this closure.

The valve body houses these components. It must be durable to withstand varying pressures. For instance, reports indicate that low pressure applications might experience pressures as low as 2 psi. Yet, the valve must still effectively prevent backflow under these conditions.

Another important aspect is the seal. This element ensures no leakage occurs between the valve and piping. Manufacturing quality is vital to achieve reliability. A flawed seal can lead to significant issues. Some studies show that over 30% of valve failures stem from improper sealing. This reveals the importance of quality control in the production of these components. The low pressure check valve may seem simple, but each area demands attention for optimal performance.

A low pressure check valve is crucial for various fluid systems, preventing backflow under reduced pressure conditions. These valves operate based on a straightforward mechanism. When the fluid flows in the desired direction, the valve opens, allowing passage. However, if the flow reverses, the valve closes, preventing any backflow.

In industry reports, it is noted that low pressure check valves are vital in applications where fluid integrity needs to be maintained. For example, in water treatment and HVAC systems, improper backflow can lead to contamination. According to recent data from the Fluid Control Trade Association, about 20% of fluid system failures relate to backflow issues, highlighting the importance of reliable check valves.

When selecting a low pressure check valve, size and flow capacity should be balanced carefully. A valve too small may not handle the required flow, leading to inefficiencies. Conversely, a larger valve can introduce unwanted pressure drops. The installation angle may also affect functionality. Industry guidelines suggest that installation should minimize potential flow disruptions. Even minor errors can lead to performance issues, necessitating careful consideration in design and setup.

Low pressure check valves play a crucial role in various industries by preventing backflow in fluid systems. These valves are essential in applications where maintaining pressure and flow direction is critical. The American Society of Mechanical Engineers (ASME) estimates that improper flow management can lead to system failures in over 20% of industrial processes. Low pressure check valves help mitigate this risk by ensuring smooth operation.

One common application is in water treatment plants. Here, low pressure check valves protect pumps from backflow, which can lead to contamination. According to a report from the Water Environment Federation, proper valve installation reduces maintenance costs by up to 30%. Similarly, they are used in chemical processing, where precise flow direction is vital to avoid hazardous reactions. The Chemical Engineering Journal highlighted that effective use of these valves can reduce incidents related to chemical spills by nearly 25%.

There are always challenges associated with low pressure check valves. Improper sizing can cause valve failure. Additionally, sediment can accumulate, leading to blockages. Regular inspections are necessary to maintain performance. The average lifespan of these valves is about 10-15 years, but this can vary significantly based on usage and maintenance practices. Attention to detail in each application ensures that low pressure check valves perform optimally and enhance system integrity.

Low pressure check valves play a critical role in fluid systems. They allow flow in one direction while preventing reverse flow. This function is vital in maintaining system efficiency. When the pressure is lower than a certain threshold, these valves open, allowing fluid to pass. If the pressure reverses, the valve closes.

One major advantage of these valves is their ability to prevent backflow. Backflow can lead to contamination. Protecting the system from mixed fluids is crucial. Additionally, low pressure check valves help reduce water hammer effects. This can prolong the lifespan of the entire system.

They are often lightweight and easy to install. However, improper alignment can cause issues. Regular maintenance is needed to ensure they function correctly. If neglected, the valve might stick or fail. It’s essential to monitor performance regularly. These valves are simple in design but significant in impact. Their efficiency can’t be overlooked.

1272 Speers Rd Unit 4

Oakville ON Canada L6L 2X4

©Copyright 2020 Gosco Valves. All rights reserved.