The importance of a non return valve cannot be overstated in fluid control systems. Dr. John Smith, a leading expert in valve technologies, once remarked, “A non return valve is vital for preventing backflow and ensuring system reliability.” This statement encapsulates the pivotal role these devices play.

Non return valves serve to maintain the directional flow of fluids. They prevent liquids from flowing backward, which can cause significant damage in piping systems. Such devices are critical in various applications, from water supply to chemical processing. Without them, systems could experience costly failures.

However, not all non return valves are created equal. Choosing the wrong type can lead to inefficiencies. Some designs may fail under high pressure, allowing backflow. This highlights the need for careful selection and installation. Understanding the specific requirements of your system is essential for optimal performance.

Non return valves play a crucial role in fluid systems. Their main function is to allow fluid to flow in one direction only. This prevents backflow, which could disrupt system efficiency. In applications like pumps and fluid transport systems, non return valves are essential to maintain pressure and enhance performance.

When a system experiences a change in pressure, backflow can occur. This can lead to equipment failure or reduce efficiency. Non return valves mitigate this risk by closing automatically when flow reverses. The simple mechanism of a flap or ball within the valve prevents fluid from returning. It's a small detail but vital in many applications.

However, not all non return valves perform equally. Some may be prone to wear, leading to malfunction over time. Users often overlook maintenance, which can result in unexpected backflow situations. Regular checks can help maintain their functionality. Understanding the specific needs of each system can lead to better choices in valve types, ensuring optimal efficiency.

Non-return valves, often called check valves, are critical in various fluid systems. They prevent backflow, ensuring that liquids or gases flow in only one direction. This feature is vital in many applications, from simple household plumbing to complex industrial processes. Different types of non-return valves serve unique needs, making them versatile tools in fluid control.

Swing check valves are commonly used in water systems. They have a hinged disc that swings open and shut based on pressure differences. This design allows for efficient flow but may not close immediately, causing some backflow. Another type, the lift check valve, uses a vertical disk to prevent backflow. It's effective in high-pressure environments but can be prone to wear over time, leading to potential leaks.

Spring check valves rely on a spring mechanism to maintain closure. They respond quickly to changes in flow, which prevents backflow effectively. However, they require regular maintenance to ensure the spring is functioning properly. Understanding these applications helps in selecting the right valve for specific needs. It's essential to consider both the advantages and potential drawbacks when choosing a non-return valve.

| Type of Non Return Valve | Working Principle | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Swing Check Valve | Uses a disc that swings on a hinge to allow flow in one direction. | Water supply, HVAC systems, and oil and gas industries. | Simple design, low-pressure drop. | Can be affected by vibration and flow turbulence. |

| Lift Check Valve | Uses a plug that moves up and down to permit or block flow. | Pipelines, water pumps, and wastewater treatment. | Compact design, suitable for high-pressure systems. | Higher pressure drop compared to swing valves. |

| Diaphragm Check Valve | Uses a diaphragm to separate flow and maintain pressure in one direction. | Chemical processing, food and beverage industries. | Effective sealing, suitable for corrosive fluids. | Limited temperature and pressure ratings. |

| Ball Check Valve | Uses a ball that lifts off its seat to allow flow. | Pumps, fire protection systems, and irrigation. | Low pressure drop, reliable operation. | Can be noisy and have issues with flow rates. |

| Wafer Check Valve | Compact design with a disc that rotates to block reverse flow. | Space-efficient applications, such as piping systems. | Lightweight, saves space. | Less durable in high-pressure applications compared to other types. |

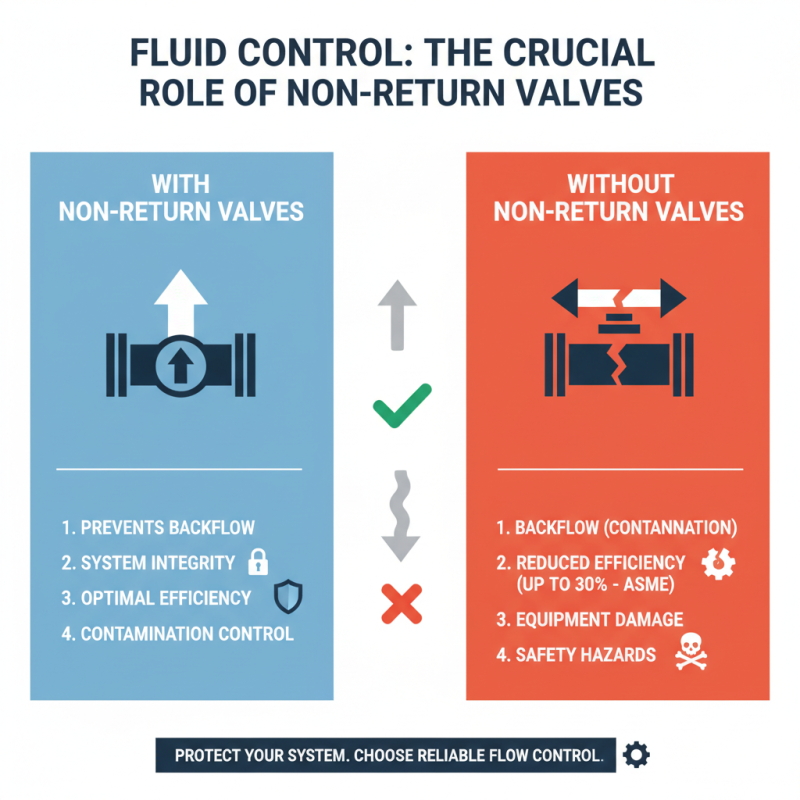

Non-return valves play a crucial role in fluid control systems. They prevent backflow, ensuring that fluids move in one direction. This feature significantly enhances system efficiency and reliability. According to industry reports, systems utilizing non-return valves can reduce energy costs by up to 30%. This is a substantial savings, especially in large operations.

Using non-return valves also minimizes the risk of contamination. When fluids flow backward, it can introduce pollutants into clean systems. This is particularly vital in sectors like pharmaceuticals and food processing. A single contamination incident can lead to costly downtime and repairs. Recent studies show that investing in quality non-return valves can decrease maintenance costs by nearly 20%.

**Tip:** Regularly inspect your non-return valves to ensure they function correctly. Small issues can escalate into larger problems if overlooked. Keeping up with maintenance leads to longer lifespans and lower operational costs.

Additionally, installing these valves might not be straightforward. They can sometimes lead to pressure drops. It’s essential to assess the system comprehensively before installation. A miscalculated choice might hinder efficiency rather than enhance it. Understanding the system's dynamics is critical.

This chart illustrates the benefits of using Non Return Valves (NRVs) in achieving fluid control efficiency across various applications.

Non-return valves play a vital role in fluid control systems. Without them, several common issues can arise. One major problem is backflow. This occurs when fluid flows in the opposite direction, causing contamination. A report from the American Society of Mechanical Engineers (ASME) indicates that backflow can reduce system efficiency by up to 30%.

Another frequent issue is system pressure fluctuation. When non-return valves are absent, pressure is unstable. This instability can lead to pump damage or failure. Studies show that systems without these valves experience a 25% increase in maintenance costs. Operators face the risk of unexpected downtimes, resulting in lost productivity.

Leaking is another concern. Without proper valves, fluid leaks may go unnoticed. This can lead to equipment wear and costly repairs. The potential for accidents also increases, making safety a serious issue. Each instance of these failures can hint at the critical need for preventive measures. Non-return valves are not just components; they are essential safeguards for efficiency and reliability.

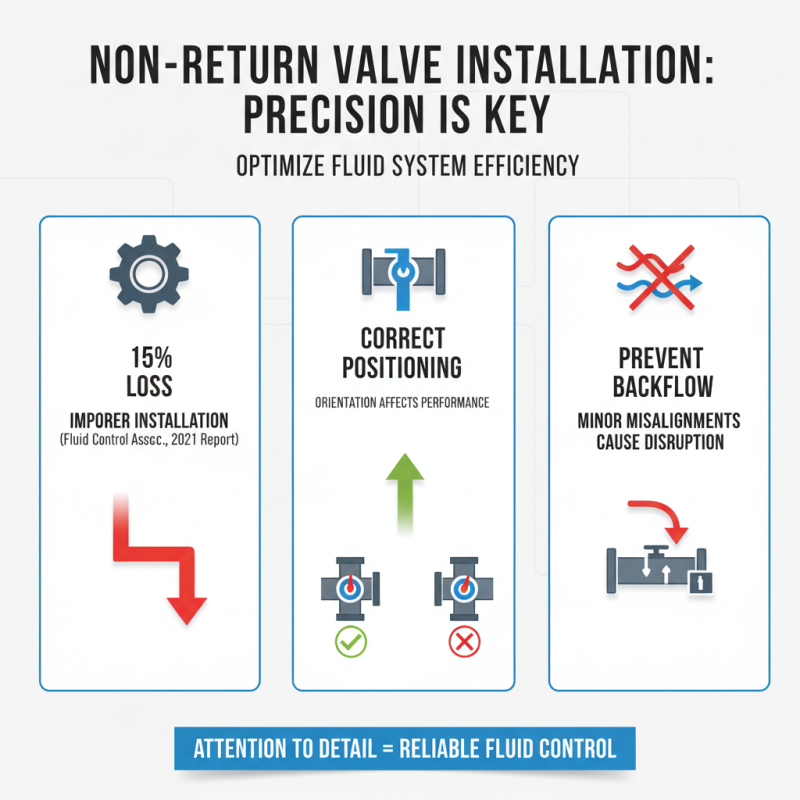

When installing non-return valves, precise attention to detail is crucial. A 2021 report from the Fluid Control Association noted that improper installation can lead to a 15% reduction in system efficiency. It's essential to ensure correct positioning, as orientation can affect the valve's performance. Even minor misalignments can result in backflow, which disrupts fluid control.

Regular maintenance is equally important. Ignoring routine checks can increase wear, leading to potential failures. Industry studies reveal that 30% of non-return valve failures stem from neglecting maintenance schedules. Cleaning the valve regularly helps remove debris and sediment buildup. This practice helps sustain optimal flow rates, ensuring the system runs smoothly.

It is also vital to select the right material for the valve based on the fluid type. A mismatch can cause corrosion and quicker deterioration. Surprisingly, many installations overlook this critical aspect. Monitoring pressure fluctuations is imperative. Failure to do so could lead to unnoticed issues, compounding over time. Being proactive in both installation and maintenance can significantly enhance overall performance.

1272 Speers Rd Unit 4

Oakville ON Canada L6L 2X4

©Copyright 2020 Gosco Valves. All rights reserved.