Pneumatic solenoid valves play a critical role in modern automation systems, controlling the flow of air and acting as essential components in various industrial applications. According to Dr. Emily Carter, a renowned expert in fluid dynamics, "The pneumatic solenoid valve is not just a switch; it is the backbone of air control in countless systems." This statement underscores the significance of this valve in managing pneumatic processes efficiently.

The functionality of a pneumatic solenoid valve lies in its ability to convert electrical energy into mechanical action, allowing for the precise control of airflow. This efficiency is paramount in industries ranging from manufacturing to automotive, where rapid response times and reliability are crucial. Understanding how these valves operate can provide deeper insights into their applications, potential challenges, and benefits in various settings.

As we delve into the specifics of pneumatic solenoid valves, we will explore their construction, operational principles, and key factors to consider when selecting the right valve for your needs. This knowledge not only enhances operational efficiency but also leads to significant cost savings and improvements in productivity across numerous industries.

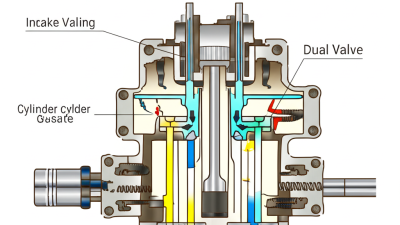

Pneumatic solenoid valves are essential components in various automated systems, particularly in industries where control over air pressure is crucial. These valves operate based on electromagnetic principles, enabling the precise control of air flow. When an electric current passes through the solenoid coil, it creates a magnetic field that actuates the valve, either opening or closing the passage for compressed air. This mechanism allows for rapid switching and is commonly employed in applications ranging from simple pneumatic tools to complex robotics.

Understanding the fundamentals of pneumatic solenoid valves involves recognizing their role in automation and process control. Just like the intricate hydraulic systems used in Formula 1 cars to manage various subsystems effectively, pneumatic valves facilitate the efficient operation of machinery and control systems. They are designed to handle varying pressures and flows, making them adaptable to different operational needs. In both cases, the underlying principle of using controlled pressure to execute precise actions is paramount, highlighting the importance of reliable components in achieving optimal performance.

A pneumatic solenoid valve is a critical component in various industrial applications, controlling the flow of air or gas in a pneumatic system. The operation of this valve hinges on an electromagnetic coil that, when energized, creates a magnetic field to move a plunger or armature. This movement allows or restricts airflow through the valve, enabling precise control over pressure and flow rate. The mechanism is simple yet effective, relying on electrical signals to manipulate pneumatic functions seamlessly.

**Tips**: Regular maintenance of your pneumatic solenoid valve is essential for optimal performance. Check for any signs of wear or damage, and ensure that the electromagnetic coil is functioning correctly to avoid unexpected downtime.

In addition to its straightforward mechanism, the responsiveness of a pneumatic solenoid valve makes it suitable for automation tasks. When designing a pneumatic system, consider the valve's specifications—such as voltage, flow rate, and pressure rating—to ensure compatibility and efficiency. Paying attention to these details can significantly enhance the reliability and longevity of your pneumatic applications.

**Tips**: Always consult the manufacturer's guidelines for installation and operation to maximize the performance and lifecycle of your pneumatic solenoid valve. Regularly inspect connections and fittings to prevent leaks, which can undermine system efficiency.

Pneumatic solenoid valves are essential components across various industries, providing an efficient means of controlling the flow of compressed air and gases. Their primary function is to facilitate the automation of processes, enabling precise control in applications such as factory automation, material handling, and the regulation of hydronic systems. The versatility of pneumatic solenoid valves allows them to be used in a wide range of sectors, including automotive, pharmaceuticals, and food processing, where reliability and accuracy are paramount.

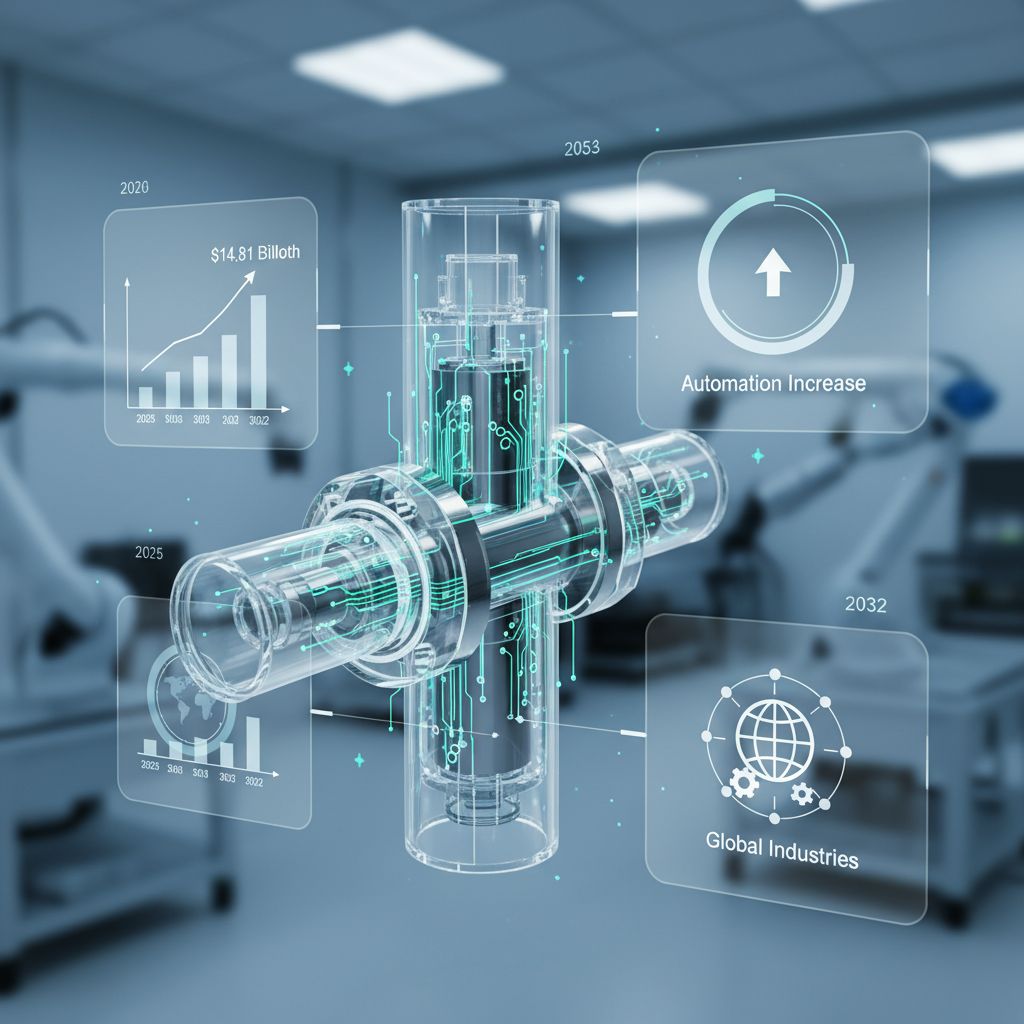

The growing demand for pneumatic components is reflected in the projected market growth, with the global pneumatic components market size anticipated to rise significantly by 2032. This expansion is driven by the integration of automation in manufacturing processes and the increasing need for energy-efficient solutions. As industries continue to adopt advanced technologies, the role of pneumatic solenoid valves in optimizing operations will only become more prominent, showcasing their vital contribution to sector innovation and efficiency.

When selecting a pneumatic solenoid valve, several key features should be taken into account to ensure optimal performance for your specific application.

First, consider the valve's response time, which is crucial for applications requiring quick actuation. A faster response time can lead to improved efficiency and control in your pneumatic system.

Additionally, assess the valve’s pressure rating, as this will determine the maximum operating pressure it can handle safely.

Another important feature is the valve’s connection type. Different systems might require various types of fittings or ports.

Therefore, ensure that the pneumatic solenoid valve you choose is compatible with your existing setup.

Tips: Before making a purchase, double-check the manufacturer's specifications and verify the compatibility with your pneumatic circuit.

Asking for recommendations from industry professionals can also be beneficial.

Additionally, consider future scalability; selecting a versatile solenoid valve can save time and resources as your system evolves.

The future of pneumatic solenoid valve technology is poised for significant advancements by 2025, as the global pneumatic components market is projected to expand substantially. With expectations of growing from $14.81 billion in 2025 to $21.58 billion by 2032, the demand for innovative pneumatic solutions, including solenoid valves, is becoming increasingly critical. This growth can be attributed to the rising automation across various industries, which requires reliable and efficient components to facilitate smooth operations.

In addition to market growth, specific segments, such as the solenoid valve market, are also experiencing notable developments. Market projections indicate that the solenoid valve sector will see an increase from $4.9 billion in 2025 to $7.6 billion by 2035, reflecting a compound annual growth rate of 4.5%. This trend highlights the importance of incorporating advanced technologies, such as proportional pressure control and miniature designs, to meet evolving industrial needs. As manufacturers focus on enhancing performance and energy efficiency, the upcoming years will likely result in groundbreaking innovations in pneumatic solenoid valve technology.

1272 Speers Rd Unit 4

Oakville ON Canada L6L 2X4

©Copyright 2020 Gosco Valves. All rights reserved.