In various industrial applications, ensuring the reliability and efficiency of fluid systems is paramount. One critical component that plays a vital role in this is the low pressure check valve. According to a report by the International Society of Automation, incorrect valve selection can lead to significant operational inefficiencies and increased maintenance costs, underscoring the importance of choosing the right low pressure check valve for any system. As systems operate under varying conditions, the ability of a check valve to maintain consistent performance at low pressures can make a substantial difference in overall system reliability.

Industry expert Dr. Michael Thompson, a leading authority on fluid dynamics and valve technology, states, "Selecting a low pressure check valve that meets the specific demands of your system is not just a matter of preference; it's essential for operational success." His insights reflect the consensus among engineers that appropriate valve selection directly contributes to reducing downtime and enhancing the longevity of hydraulic systems. With advancements in materials and design, the available options are diverse, making it crucial for manufacturers and operators alike to stay informed about the top choices in the market.

This guide aims to provide an overview of the top 10 low pressure check valves known for their dependable performance. By analyzing key features and specifications, users can equip their systems with the best possible components to maximize efficiency and minimize potential failures.

Low pressure check valves play a crucial role in various fluid systems by allowing flow in one direction while preventing backflow. Their significance lies in enhancing system reliability and efficiency, particularly in applications where pressure fluctuations are common. According to a recent industry report, effective backflow prevention can enhance system longevity by up to 30%, a critical consideration for operators seeking to minimize downtime and maintenance costs.

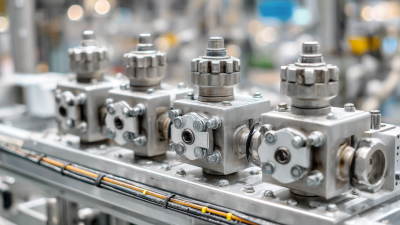

In industries such as water treatment, HVAC, and chemical processing, low pressure check valves ensure that systems operate smoothly under varying conditions. These valves are designed to function effectively at lower pressure levels, typically ranging from 0.5 to 10 PSI. The global check valve market is projected to grow significantly, driven by the increasing demand for efficient fluid control solutions. Furthermore, data from engineering studies indicates that the use of reliable check valves can optimize energy consumption within these systems, reducing operational expenditures by as much as 15%.

Understanding the different types of low pressure check valves and their applications can aid in making informed decisions about system design and maintenance. By selecting the appropriate valve for specific needs, operators can enhance the overall performance and reliability of their systems, ensuring that they meet the rigorous demands of modern operations.

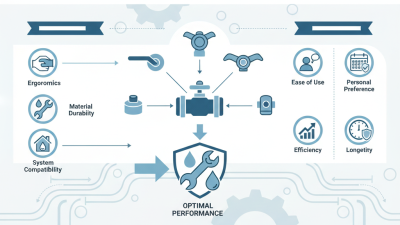

When selecting low pressure check valves for your system, there are several key features to consider that can significantly impact performance and reliability.

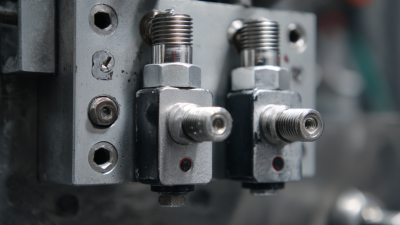

Firstly, the material of the valve is crucial. Valves made from corrosion-resistant materials such as stainless steel or high-grade plastics will ensure durability and longevity, especially in environments where chemical exposure is a concern. Additionally, the construction design, whether it is a spring-loaded, diaphragm, or poppet type, affects how the valve operates under varying pressure conditions. It's essential to choose a design that aligns with your system's specifications to guarantee optimal function.

Another important feature to consider is the flow rate and pressure drop characteristics of the valve. A well-designed check valve should minimize pressure losses while allowing for smooth and efficient flow. Ensure that the valve can handle the expected flow rates in your application without compromising performance. Furthermore, consider the ease of installation and maintenance. Valves that can be serviced easily without requiring extensive disassembly will save time and reduce costs in the long run. Overall, focusing on these key aspects will help you select a low pressure check valve that meets the demands of your system effectively.

When selecting a low pressure check valve for your system, there are multiple models available that ensure reliable performance across various applications. These valves are designed to prevent backflow, maintaining the desired pressure and flow rate while safeguarding your system’s integrity. Common materials used in their construction include plastics and metals, offering durability and resistance to wear and tear from fluid dynamics.

Tips for choosing the right low pressure check valve include evaluating the specific requirements of your system, such as the type of fluids involved and the operating pressure range. It’s advisable to consider factors like maintenance needs and compatibility with existing piping systems. Proper installation is crucial; ensure that the valve is oriented correctly and that all connections are secure to maximize performance.

Another important aspect is to assess the size and flow characteristics of the valve. A mismatched valve can lead to inefficiencies or pressure drops. Regular inspections and maintenance practices will also help to extend the lifespan of your check valve, ensuring it continues to perform optimally. Always be proactive in monitoring signs of wear or leakage, and address any issues promptly to keep your system running smoothly.

| Model | Size (inch) | Material | Max Pressure (psi) | Temperature Range (°F) | Weight (lbs) | Connection Type |

|---|---|---|---|---|---|---|

| Model A | 1 | Brass | 150 | 32 to 180 | 2.5 | Threaded |

| Model B | 1.5 | PVC | 75 | 40 to 140 | 1.8 | Socket |

| Model C | 2 | Stainless Steel | 200 | -20 to 250 | 3.2 | Flanged |

| Model D | 0.75 | Bronze | 125 | 32 to 180 | 1.5 | Threaded |

| Model E | 1 | Aluminum | 90 | 0 to 200 | 2.1 | Push-to-Connect |

| Model F | 2.5 | Cast Iron | 150 | 32 to 220 | 4.5 | Flanged |

| Model G | 1.25 | Nylon | 60 | 32 to 140 | 1.2 | Threaded |

| Model H | 0.5 | POM | 40 | 32 to 158 | 0.9 | Barbed |

| Model I | 3 | Steel | 250 | -20 to 300 | 5.0 | Flanged |

| Model J | 1.75 | Copper | 180 | 32 to 200 | 3.0 | Solder |

When selecting low pressure check valves for your system, a comparative analysis of available options can significantly enhance performance and reliability. Low pressure check valves are essential in various applications, enabling fluid flow in one direction while preventing backflow. A thorough examination of features such as materials, size, and sealing mechanisms helps identify which valve fits your needs best.

One key feature to consider is the material composition of the valve. Valves made from high-grade materials such as stainless steel or durable plastics offer enhanced resistance to corrosion and wear, making them suitable for long-term use in various environments. Additionally, ensure that the size fits your piping system to avoid leakage and ensure optimal flow rates.

Tips: Regular maintenance checks on your low pressure check valves can prolong their lifespan and prevent unexpected failures. Additionally, consider investing in valves with easy access for cleaning and repairs. This proactive approach will ensure that your system remains efficient and reliable over time. Always consult with professionals to match specific valve characteristics with your system's requirements.

To maintain the longevity and reliability of your low-pressure check valves, regular inspections are essential. Check for any visible signs of wear, corrosion, or leakage, as these can affect the valve’s performance. It's beneficial to create a routine maintenance schedule that allows for timely replacement or repair, ensuring that your system operates smoothly without unexpected interruptions.

Tips for maintaining check valves include not only regular visual inspections but also keeping the surrounding area clean and free of debris, which can interfere with their function. Additionally, ensure that the valve is properly aligned within the system to prevent undue stress on the components. Using protective covers can also help safeguard against environmental factors that may lead to premature wear.

Another useful practice is to monitor the pressure levels within your system closely. Fluctuations or deviations from expected ranges can indicate issues related to your check valves or the overall system. Addressing any irregularities immediately will help maintain the integrity of the check valves and enhance their operational lifespan.

1272 Speers Rd Unit 4

Oakville ON Canada L6L 2X4

©Copyright 2020 Gosco Valves. All rights reserved.