In the intricate world of hydraulic systems, the efficiency and reliability of fluid control mechanisms play a crucial role in optimizing performance. At the very heart of these systems lies the directional valve, an essential component that governs the flow of hydraulic fluid, directing it to various actuators and ensuring smooth operation. As industry expert Dr. William Hargrove succinctly emphasizes, “Directional valves are the gatekeepers of hydraulic efficiency; without them, systems would falter in their fundamental purpose.”

In recent years, advancements in technology have ushered in a new era of directional valve solutions, promising enhanced performance and reliability for hydraulic applications across various sectors. These innovations not only aim to improve energy efficiency but also to reduce response times and extend the service life of hydraulic systems. As we explore the top 10 directional valve solutions, we will highlight key features and benefits that cater to modern demands while addressing the ever-evolving challenges of the industry.

This article will provide valuable insights into the latest trends and technologies shaping the future of directional valves, showcasing how they contribute to improved operational excellence. By understanding and leveraging the capabilities of these solutions, engineers and designers can significantly enhance the performance of hydraulic systems, leading to better outcomes in operational efficiency and sustainability.

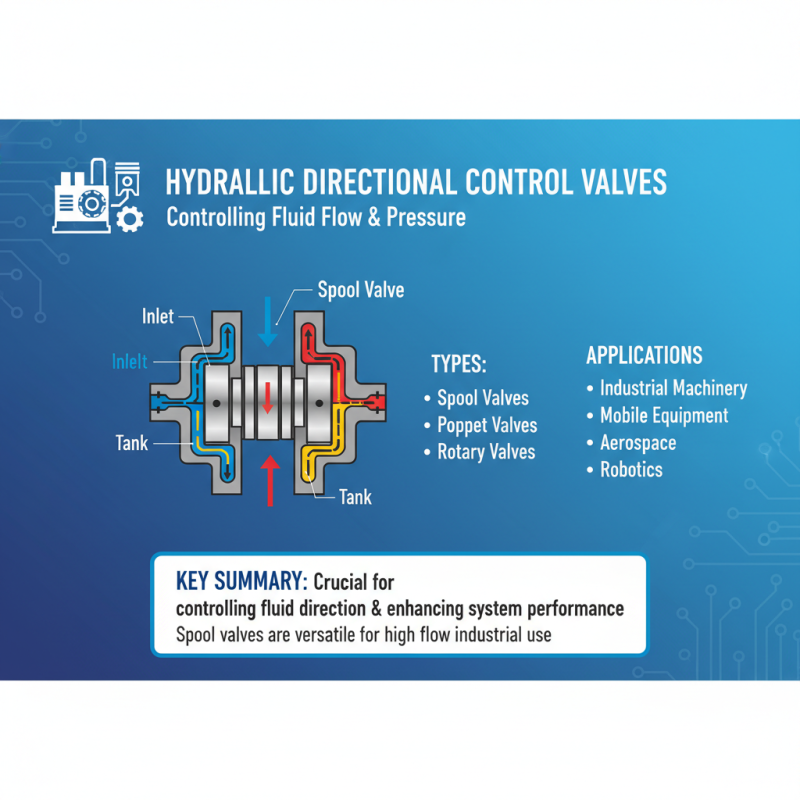

Directional valves play a pivotal role in hydraulic systems by controlling the flow direction of hydraulic fluid, thereby determining the operation of various hydraulic actuators. According to industry reports, directional valves account for approximately 30% of the total hydraulic component market, reflecting their critical function in the efficiency and effectiveness of hydraulic machinery. By utilizing advanced technologies, these valves enhance performance metrics such as response time, reliability, and precision control, which are essential for modern hydraulic applications.

When selecting directional valves for enhanced hydraulic performance, it is crucial to consider factors like flow rates, pressure ratings, and installation flexibility. For instance, choosing valves with higher flow capacity can significantly improve system efficiency, allowing for faster actuation and reduced energy consumption. Additionally, incorporating features such as proportional control can enhance the system's adaptability to varying load conditions.

Tips: Regular maintenance of directional valves, including checking for leaks and ensuring proper calibration, can optimize their performance and extend the lifespan of the hydraulic system. Furthermore, understanding the specific operational requirements of your application will aid in choosing the right valve configuration, ultimately leading to improved operational efficiency.

| Rank | Valve Type | Flow Rate (L/min) | Operating Pressure (bar) | Response Time (ms) |

|---|---|---|---|---|

| 1 | Electro-Hydraulic Valve | 150 | 350 | 30 |

| 2 | Solenoid Valve | 100 | 300 | 25 |

| 3 | Pneumatic Valve | 90 | 250 | 20 |

| 4 | Pilot Operated Valve | 200 | 400 | 15 |

| 5 | Directional Control Valve | 120 | 320 | 35 |

| 6 | Check Valve | 80 | 220 | 40 |

| 7 | Flow Control Valve | 110 | 340 | 22 |

| 8 | Hydraulic Relief Valve | 70 | 200 | 18 |

| 9 | Directional Spool Valve | 130 | 360 | 28 |

| 10 | Last Chance Valve | 60 | 180 | 50 |

When evaluating hydraulic directional valves, several key performance metrics are crucial for optimizing system efficiency and functionality. One of the foremost metrics is the flow rate, which significantly influences the speed and responsiveness of hydraulic operations. A valve with a higher flow rate facilitates quicker actuation of hydraulic cylinders or motors, essential for applications requiring rapid movement or dynamic control. Additionally, valve responsiveness, often characterized by the time taken for the valve to transition from one position to another, plays a vital role in ensuring smooth operation and minimizing delays in hydraulic systems.

Another important performance metric is the pressure rating of the directional valve. This determines the maximum pressure the valve can withstand while maintaining operational integrity. A higher pressure rating can enhance the valve's suitability for demanding applications, where high forces are required. Additionally, factors such as leakage rates and temperature compatibility are also essential to consider. Minimal leakage not only improves efficiency but also reduces wear and tear, prolonging the service life of the valve. Meanwhile, appropriate temperature ratings ensure reliable performance under varying environmental conditions, minimizing the risk of failure and ensuring system stability. Overall, assessing these key performance metrics is fundamental to selecting the best directional valve solution for enhanced hydraulic performance.

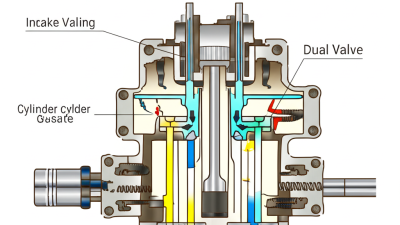

Directional valves are crucial components in hydraulic systems, playing a key role in controlling fluid flow and pressure in various applications. Understanding the different types of directional valves and their specific applications can significantly enhance hydraulic performance. For instance, spool valves are widely used in industrial machinery due to their versatility and ability to control large flow rates. They can effectively manage the direction of fluid through the system, ensuring that machines operate smoothly and efficiently.

Another important type of directional valve is the poppet valve, which excels in high-pressure applications. Its design allows for rapid actuation and reliable sealing, making it suitable for systems that require immediate response and high reliability. Additionally, rotary valves can be utilized in applications that demand a more compact solution, such as mobile equipment. Their unique design permits efficient control of multi-directional flow in a limited space, thereby improving the overall system performance.

Tips: When selecting a directional valve, consider the specific flow requirements and pressure ratings of your application. Ensure that the components are compatible with the hydraulic fluids being used to prevent degradation over time. Regular maintenance and testing can also help identify potential issues early, thereby prolonging the lifespan of the hydraulic system.

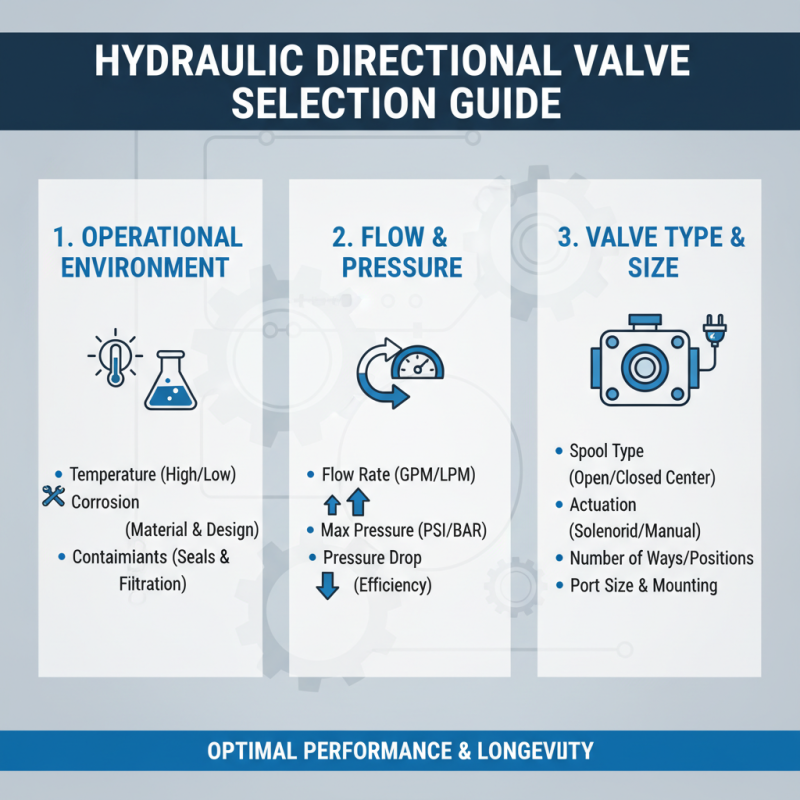

When selecting directional valves for hydraulic systems, several factors must be considered to ensure optimal performance and longevity. One of the primary elements is the operational environment. In demanding conditions, such as high temperatures or corrosive environments, the material and design of the valve become crucial. The valve must be capable of withstanding external factors while maintaining consistent performance. Additionally, the expected flow rates and pressure levels are critical in determining the appropriate size and specifications of the valve.

Another key factor influencing the selection of directional valves is the application’s specific requirements. Different applications may necessitate distinct configurations, such as spring-return actuation or float positions. The technology used in the valve, such as solenoid versus manual operation, also plays a pivotal role based on the level of automation desired. Furthermore, compatibility with existing hydraulic components is essential; ensuring that the valve integrates seamlessly into the system can prevent compatibility issues and enhance overall efficiency. By carefully evaluating these factors, one can select the most suitable directional valve to ensure enhanced hydraulic performance.

The advancements in hydraulic directional valve technology are poised to reshape the landscape of industrial applications, driven by increasing demands for efficiency and sustainability. According to a recent report by industry analysts, the global hydraulic valves market is projected to grow at a CAGR of 4.2% from 2022 to 2028. This growth is primarily fueled by the rising adoption of automated systems and the need for precise control in hydraulic applications, highlighting the critical role that directional valves play in enhancing overall hydraulic performance.

One of the key trends in the evolution of hydraulic directional valves is the integration of smart technology. The incorporation of IoT (Internet of Things) capabilities allows for real-time monitoring and diagnostics, significantly improving maintenance practices and operational efficiencies. Research indicates that systems employing smart valves can reduce downtime by up to 20%, as predictive analytics enable proactive maintenance. Furthermore, developments in materials and manufacturing processes are leading to lightweight and environmentally friendly valve designs, reflecting a shift towards sustainability while maintaining high performance levels.

Moreover, the application of electro-hydraulic and proportional control technologies is enhancing the precision with which hydraulic systems operate. These innovations enable smoother and more responsive control of flow rates and pressures, resulting in improved system efficiency and reduced energy consumption. A study by a leading engineering firm suggests that implementing advanced hydraulic control systems can yield energy savings of up to 30%, underscoring the economic and environmental benefits of adopting cutting-edge directional valve technologies in hydraulic systems.

1272 Speers Rd Unit 4

Oakville ON Canada L6L 2X4

©Copyright 2020 Gosco Valves. All rights reserved.