In the ever-evolving landscape of industrial applications, choosing the right valve packing is crucial for performance and durability. According to a recent report by Grand View Research, the global valve packing market is anticipated to reach $2 billion by 2026, reflecting a growing recognition of its importance. Valve packing not only prevents leaks but also enhances the lifespan of valves in various conditions.

Different materials and designs are available, including PTFE, graphite, and rubber, each tailored for specific applications. Interestingly, the choice of valve packing often hinges on the operational environment. A study published in the Journal of Fluid Engineering highlights that improper selection can lead to increased maintenance costs and reduced efficiency. This underscores the need for careful consideration and testing.

However, the industry often overlooks emerging options. Newer technologies may offer enhanced properties but are not widely adopted. There is a gap in awareness about innovative materials that could improve reliability. As we look into 2026, it's imperative for professionals to reflect on current choices and explore advanced valve packing solutions for optimal results.

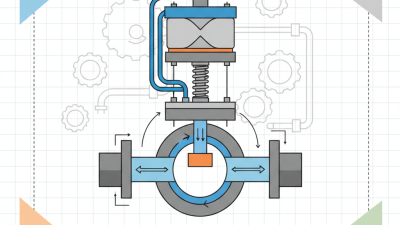

Valve packing plays a critical role in various industries. It seals fluid or gas in valves to prevent leakage. Several types of valve packing are available, each suited for specific applications. Common materials include graphite, PTFE, and aramid fibers. Each type has distinct advantages and limitations.

Graphite packing is known for its thermal resistance and durability. It's ideal for high-temperature environments. However, it may not provide sufficient sealing under low-pressure conditions. On the other hand, PTFE packing provides excellent chemical resistance but can wear out quickly under high mechanical stress. This trade-off must be carefully evaluated.

**Tips:** When selecting valve packing, consider the operating environment. Analyze temperature and pressure ranges. This can significantly impact the packing's effectiveness.

Aramid fiber packing is often chosen for its strength and flexibility. It's suitable for applications requiring resistance to chemicals and abrasion. Yet, improper installation can lead to premature failure. Always ensure tight installation.

**Tips:** Regular inspection of valve packing can extend its lifespan. Look for signs of wear or damage. Prompt replacement can save costs in the long run.

| Packing Type | Material | Applications | Temperature Range (°F) | Pressure Rating (psi) | Life Span (years) |

|---|---|---|---|---|---|

| PTFE Packing | PTFE | Chemical Processing, Water Treatment | -320 to 500 | 4000 | 5-10 |

| Graphite Packing | Graphite | High-Temperature Applications, Oil & Gas | -450 to 800 | 3000 | 10-15 |

| Aramid Packing | Aramid Fiber | Water, Sewage, Pump Applications | -40 to 500 | 2000 | 3-5 |

| PTFE Composite Packing | PTFE + Filler Materials | Valves, Pumps in Various Industries | -350 to 500 | 3000 | 5-8 |

| Fiberglass Packing | Fiberglass | Steam, High-Pressure Applications | -40 to 1000 | 1500 | 7-10 |

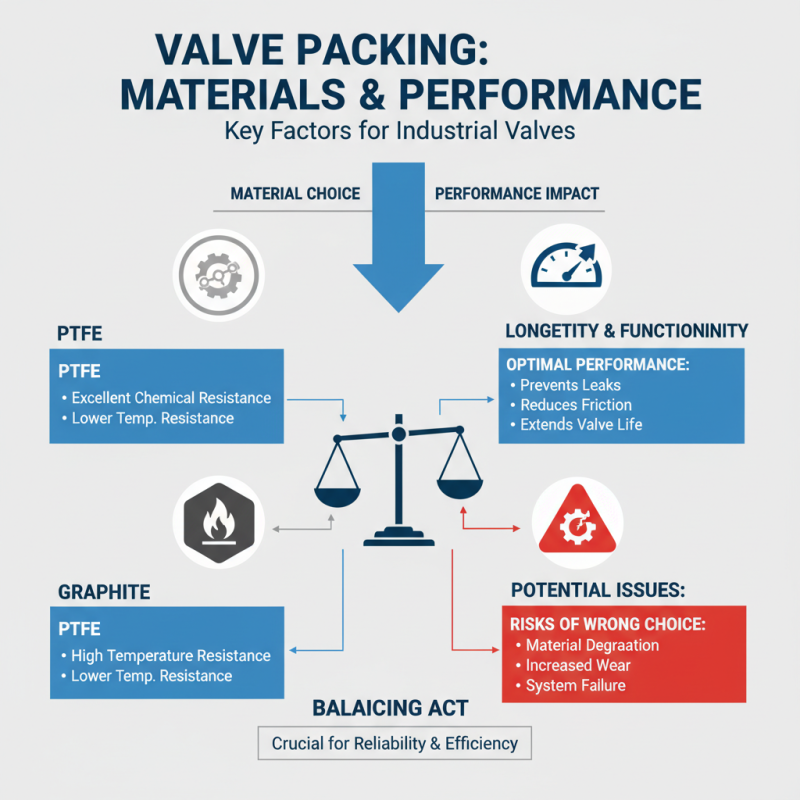

Valve packing plays a crucial role in the functionality and longevity of industrial valves. Several factors significantly impact its performance. Material choice is essential. Different materials, such as PTFE and graphite, have unique properties. PTFE offers excellent chemical resistance but may lack temperature resistance. Graphite can withstand high temperatures but might degrade in harsh chemicals. Balancing these factors can be tricky.

Another key factor is the packing design. The geometry and compression of the packing material affect sealing capability. Proper installation also matters. Misalignment can lead to premature wear. Additionally, the environmental conditions, including temperature and pressure, directly influence valve packing performance. High-pressure systems may require special considerations. An often-overlooked detail is routine maintenance. Regular checks can prevent minor issues from escalating.

Engineers often grapple with these complexities. They must weigh performance against durability. The goal is to find a packing solution that meets specific operational demands without compromising quality. Reflection on past experiences reveals that not all options yield ideal results. Each application may require a tailored approach, leading to a trial-and-error process. This highlights the importance of continuous learning in valve packing selection.

When it comes to valve packing, materials play a crucial role in ensuring performance and durability. Common options include PTFE, graphite, and aramid fibers. Each material has unique properties that may suit different applications. PTFE offers excellent chemical resistance and a low coefficient of friction. However, it can degrade under extreme temperatures. Graphite provides thermal stability and good sealing capabilities but may require additional lubricants.

Aramid fibers are known for their strength and durability. They can withstand high pressures and are resistant to abrasion. Yet, they may not perform well in highly corrosive environments. Choosing the right material can be tricky. Not all applications will benefit from the same packing material. Understanding the specific requirements of your system is vital. Regular maintenance and inspections are also necessary. Even the best materials can fail if not monitored properly.

In real-world applications, it's common to see failures related to improper material choice. Users often overlook environmental factors, leading to reduced lifespan. It's essential to reflect on past experiences to avoid repeating mistakes. Seeking guidance from experts can help in making informed decisions. Evaluating the pros and cons of each material can ultimately enhance performance and durability.

In 2026, valve packing technology continues to evolve, offering new solutions for performance and durability. With industries pushing for better efficiency, innovative materials are emerging. Advanced composites are now used to enhance strength and reduce wear. These materials can withstand extreme temperatures and pressures. This helps maintain sealing integrity over time.

Another exciting development is the use of smart technology in valve packing. Sensors embedded in the packing can monitor performance in real-time. They provide data on wear and potential leaks. This allows for proactive maintenance, reducing unexpected downtime. However, integrating such technology can be costly and complex, posing challenges for manufacturers.

Sustainability is also a key focus. Biodegradable packing materials are being explored. These materials offer a greener alternative but still face challenges in durability. Finding the right balance between performance and environmental impact remains a concern. As the industry advances, ongoing experimentation will be crucial to overcoming these hurdles.

This chart illustrates the performance ratings of various valve packing options anticipated for 2026. The ratings are based on their durability and efficiency, highlighting that Graphite Packing leads with a score of 9, while Rubber Packing has the lowest performance rating.

Proper installation and maintenance of valve packing are crucial for optimal performance. According to a report by the Valves Industry Association, improper sealing can lead to a staggering 30% productivity loss in industrial processes. This highlights the need for meticulous attention during installation. Ensure you follow the manufacturer's guidelines closely. Even small mistakes can lead to significant issues later on.

Regular maintenance is equally important. Research shows that valves require inspection every six months for optimal efficiency. Simple actions like tightening packing nuts or replacing worn materials can extend the life of valve packing. However, over-tightening can cause packing to wear prematurely, leading to leaks. Balancing these aspects is crucial.

Operators often rely on visual inspections or pressure testing to evaluate packing conditions. Still, these methods may not always detect hidden damage. Using advanced monitoring technologies can improve accuracy. Investing in these technologies can lead to better decision-making. Ignoring valve packing maintenance could ultimately affect operational integrity and increase costs.

1272 Speers Rd Unit 4

Oakville ON Canada L6L 2X4

©Copyright 2020 Gosco Valves. All rights reserved.